EPC for Anode Materials Complete Line Equipment: an Overall Intelligent Energy-saving Scheme

As a wholly-owned subsidiary of KEDA Industrial Group Co., Ltd. (Established in 1992 and stock code: 600499), KEDA(Anhui) Lithium Equipment Co., Ltd. is specialized in the R&D and manufacturing of lithium-ion battery materials machinery. The company holds many independent intellectual property core patents for anode material integration projects, covering continuous pre-carbonization rotary kiln, integrated rotary kiln for continuous granulation and pre-carbonization, automatic crucible loading system and pneumatic conveying system, etc. The company is able to provide customers with a complete set of system energy solutions for anode material integration project and aims to deliver optimal and overall energy-saving solutions by fully utilizing and recycling system energy, and upgrade the traditional production line of artificial graphite anode material to a clean and green intelligent manufacturing factory which integrates automation and intelligence.

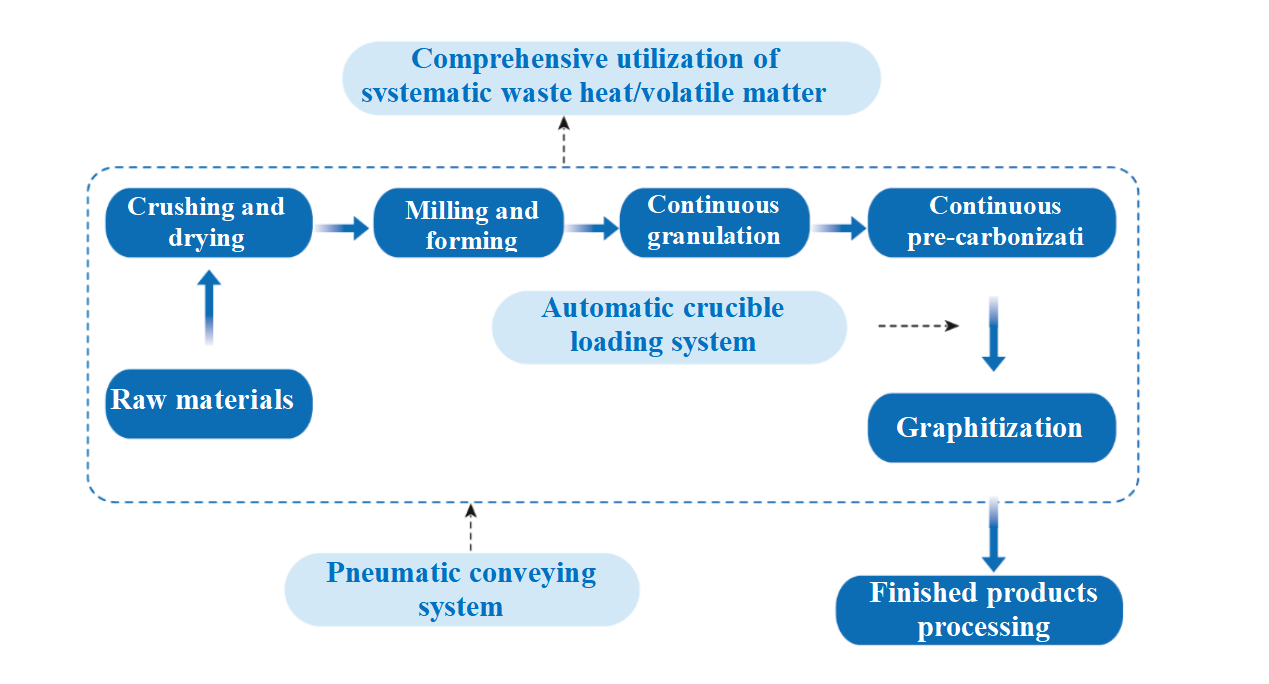

EPC flowchart for anode materials complete line machinery

Relying on an efficient R&D team, a good production system, professional machinery manufacturing experience and a complete supply chain system, the company provides customers with full life cycle services for the projects, ensuring a rapid delivery of projects. Meanwhile, a comprehensive after-sales service tracking system is established to respond quickly and solve problems actively. The company makes all the efforts to make customers feel comfortable, reassuring and free from worries.

Various Automated Single Equipment: to Assist the Whole Production Line of Anode Materials

The continuous pre-carbonization rotary kiln independently developed and manufactured by the company has been successfully applied in the pre-carbonization process of the integrated project for anode materials. The rotary kiln can fully utilize the volatile matter of the raw material as a heat source, and basically has no consumption of external fuel. The heating temperature can reach 1050℃ and the volatile content of the product is less than 0.5%. Moreover, there is no loss of spilling materials during the production process and the pre-carbonization yield is high. At the same time, the rotary kiln’s unique separation device contributes to a material loss rate ≤ 1%, and the material yield is at least 2 points higher than other types of equipment. This feature alone would save the owner approximately RMB 3 million in material losses for every 10,000 tons of annual production capacity.

Continuous pre-carbonization rotary kiln

There is no complex loading and unloading system compared to traditional tunnel kilns. Adopting DCS or PLC automation control system, the kiln greatly reduces labor cost through online detection and safety interlocking measures. The equipment is easy to operate and control, with minimal daily maintenance. Its floor area is less than 20% and the production and operation cost is less than 30% of the traditional tunnel kiln, greatly reducing production costs for customers.

Automatic crucible loading system

In addition, the automatic crucible loading system for graphitization developed by KEDA helps to achieve an automated production line that integrates automatic opening and covering, material suction, transportation and loading through an automated control system. It is mainly used in tunnel kilns and graphite charging and discharging processes. The equipment operates with high frequency and low amplitude through spiral extrusion inside and vibration outside, so the loading density of materials can reach 90% of the tapping density. The system employs a lifting structure and negative pressure material locking mechanism, which eliminates dust pollution and bounce-back of materials during the loading process, resulting in a clean and safe working environment on-site. The transportation between various processes adopts roller conveying and laser induction, making the crucibles accurately positioned between each process, with a high degree of automation. KEDA designs, develops, and manufactures multiple series of automatic crucible loading systems to meet different customer needs, including KDZG-2, KDZG-4, and KDZG-6, with a loading capacity of 10,000 to 50,000 tons per year.

The pneumatic conveying system, an important link in the whole production line, is a closed and negative pressure pneumatic conveying system equipped with an automated control system for a centralized control throughout the factory, which help to achieve continuous, automatic and no-leakage transportation inside and between each process of the anode materials production line. The site is clean and non-polluted, and the operation energy consumption is low.

Aerial view of the Company

Since the second half of 2022, KEDA(Anhui) Lithium Equipment has achieved remarkable results in several machinery and equipment projects such as pre-treatment and finished product lines, automatic crucible loading systems, and continuous granulation/pre-carbonization rotary kilns, demonstrating the full recognition and approval from users for the anode materials machinery and equipment of KEDA(Anhui) Lithium Equipment. Guided by technical advancement and driven by continuous reform, KEDA(Anhui) Lithium Equipment constantly improves the operation mechanism, the ability of resource control and operation management level of the enterprise. Being devoted to the research and application of cutting-edge technologies in lithium-ion battery materials machinery, KEDA(Anhui) Lithium Equipment continuously creates value for customers.

(Shufang PENG, KEDA(Anhui) Lithium Equipment)

loading...

loading... 16 Jun 2023

16 Jun 2023