This achievement underscores the company's exceptional performance in the field of intelligent manufacturing, earning authoritative recognition!

As a leading enterprise in China's ceramic kiln industry, DLT has pooled Chinese and international resources. After over a year of preparation, R&D, implementation, and trial operation, the company has pioneered the establishment of the first "digitalized and intelligentized manufacturing workshop" in the kiln manufacturing industry, setting a benchmark in China and internationally.

The successful evaluation serves as a testament to the industry's authoritative certification and sets a benchmark demonstration sample for the entire industry to emulate.

Empowering through digital intelligence:

Digital intelligence is an inevitable path for enterprises to refine management and upgrade industries. By establishing digitalized workshops, DLT has developed a leading-edge digital framework system.

Digital intelligence is an inevitable path for enterprises to refine management and upgrade industries. By establishing digitalized workshops, DLT has developed a leading-edge digital framework system.The introduction of intelligent machinery and the integration of 2D and 3D design software, fluid dynamics simulation software, PLM systems, SAP, MES, SRM, BI, SCADA, energy management systems, AGV scheduling systems, and other foundational infrastructure and tools have enabled end-to-end digitization and informatization.

This comprehensive approach has laid a solid foundation for intelligent control, marking a transformative journey from "0" to "1". Innovatively, it has crafted a distinctive "Creation + Quality Manufacturing + Intelligent Manufacturing" intelligent management model tailored to the unique characteristics of our enterprise.

This is achieved through the digitization of research and development design, quality management, operational management, and fostering a culture of innovation to enhance management capabilities. It involves creating a culture of transparent quality, digitizing quality improvement information for all staff, implementing zero-defect management, and ensuring quality control throughout the entire process to develop high-quality manufacturing capabilities.

Furthermore, it involves digitizing planning control, fully automating production information, implementing intelligent warehousing, and digitizing intelligent quality monitoring to develop intelligent manufacturing management capabilities.

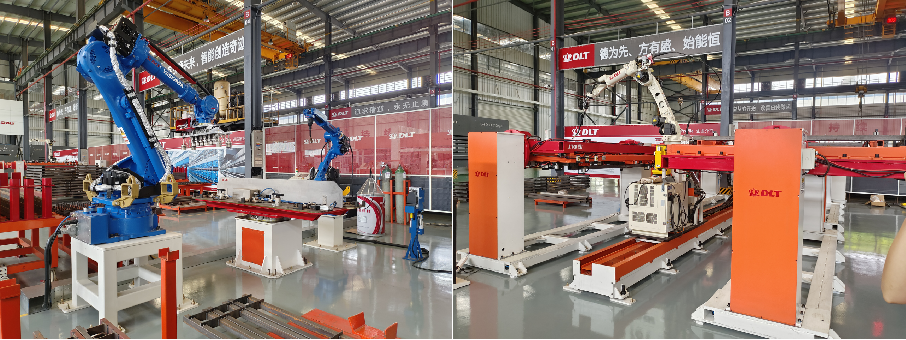

Furthermore, DLT has led the development of integrated manufacturing machinery through process reengineering, pioneering advanced manufacturing machinery in China and internationally.

This includes the kiln industry's first robot welding workstation, fully automated production lines for cutting, rolling and welding, intelligent flange production lines (integrating processes from material entry to completion in one step), and 3D wire forming machines, among other CNC machining machines.

These initiatives have not only enhanced digital intelligence capabilities but also filled gaps in both Chinese and international markets.

Harnessing the power of digital intelligence technology, DLT is forging ahead as the engine of high-quality development. In the future, DLT will continue to intensify its efforts in digital transformation, actively explore innovative development models, and strive to become a global leader in digital intelligent manufacturing.

(DLT)

loading...

loading... 17 Mar 2024

17 Mar 2024