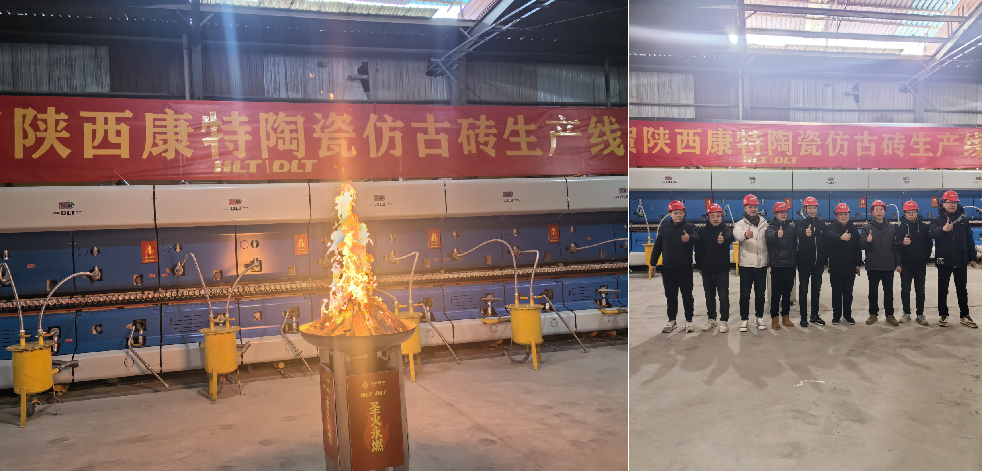

Enthusiastic individuals sway torches as roaring flames ignite the fervor of the new spring, heralding a momentous occasion for KangTe Ceramics in the Year of the Chinese Loong—a successful ignition of the new line for antique bricks!

Amidst the joyous commencement of the new year, symbolizing renewal and optimism, a grand ignition ceremony takes place. This milestone signifies KangTe Ceramics' strides towards product specialization and diversification, alongside its endeavors in intelligent manufacturing upgrades and scale expansion, swiftly embarking on a new journey of development.

KangTe Ceramics was established in 2012, spanning an area of 140,000m² with a total investment of RMB 180 million. It boasts 2 modern and intelligent production lines dedicated to producing high-end interior wall tiles and floor tiles, with a daily output of 40,000m² of various ceramic tiles. Its products are renowned for their popularity in the northwest region.

Since its inception, KangTe Ceramics has made significant investments in upgrading and improving its environmental facilities. It actively aligns with environmental standards and policies, aiming to catch up with industry leaders by continuously enhancing its management systems and establishing a dedicated product research and development team. Through these efforts, it produces eco-friendly, premium-quality products that grace countless households.

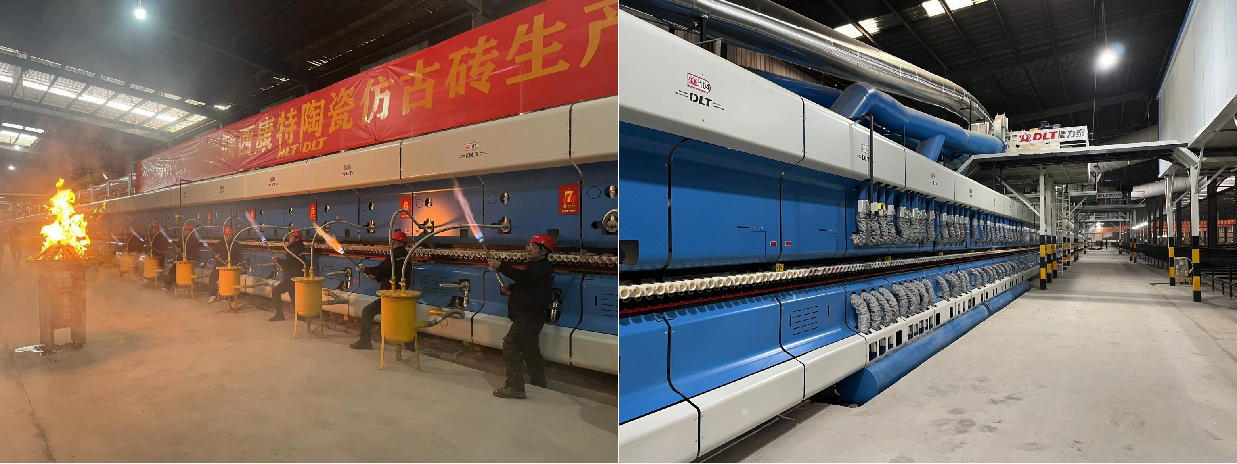

To meet the demand for quality-driven experiences amidst consumer upgrading and cater to the upscale market trends, the core machinery for the second modernized technological transformation line has been meticulously selected after comprehensive research and comparison.

In partnership with HLT&DLT, the machinery lineup includes 4 units of the widely acclaimed HLT YP4009 automatic hydraulic presses, 1 line of DLT industrial "4.0 Energy Efficiency Benchmark Smart Era" DFC firing kiln (W3100/L336M), and an EM series efficient and energy-saving self-circulation four-layer dryer, along with dryer before kiln.

It primarily produces high-quality antique bricks with specifications of 600×600mm, 800×800mm, and 600×1200mm, with thickness ranging from 8 to 10mm. The designed daily production capacity is 33,000m².

The HLT YP4009 automatic hydraulic press stands as the benchmark of energy efficiency within the 09 series, boasting a maximum pressing force of 40000kN and a pressing frequency of 12 times per minute. Its optimized hydraulic system enhances overall performance, ensuring greater power, safety, and reliability, thus meeting the operational requirements of high capacity, low consumption, and high yield.

The main unit adopts steel wire winding structure, minimizing stress concentration and ensuring the frame ample rigidity, thereby exhibiting exceptional fatigue resistance and stability. Utilizing multiple patented technologies, it offers advantages such as high flatness, precision, and rapid pressing speed, making it an environmentally friendly machinery of exceptional standards and stringent requirements. Consequently, it enjoys widespread favor among Chinese and international customers.

The firing kiln assembly incorporates the advanced DDI4.0-A intelligent central control system in its design, enabling cloud computing and comprehensive management of the overall production line operation. This breakthrough in time and space allows for remote monitoring of the production line, providing comprehensive insights into machinery operation status.

To elevate the levels of automation, informatization, and intelligence to unprecedented heights, the firing kiln also integrates DLT patented KPR combustion air heating energy-saving system and PPC combustion air grouping control system, alongside high-precision energy-saving burners, resulting in a significant enhancement of complete production line energy efficiency.

Additionally, the EM series efficient and energy-saving self-circulation four-layer dryer boasts excellent sealing, high drying efficiency, damage-free operation, space-saving design, and stable performance. It exhibits remarkable adaptability to low-intensity formulations for adobe brick, enabling the rapid, low-temperature, and efficient provision of qualified adobe bricks for firing. This results in scientific management, clean production, and energy conservation, thereby achieving substantial reductions in energy consumption.

KangTe Ceramics ushers in auspicious tidings with the arrival of the new spring, while HLT&DLT takes another stride towards excellence! The successful ignition of this project signifies a new chapter for KangTe Ceramics, paving the way for its transformation, upgrade, and expansion of product system layout.

In the upcoming year, as KangTe Ceramics strives to enhance production capacity, reduce costs, and improve efficiency, HLT&DLT will remain dedicated to market support and brand building efforts. Together, both entities embark on a fresh journey, carrying renewed hopes into the future.

(HLT&DLT)

loading...

loading... 04 Mar 2024

04 Mar 2024