Foshan, Guangdong, renowned for its ceramic industry, boasts a history of over 5,000 years. Since the introduction of the first Italian architectural ceramic production line in Foshan in the 1980s, the development of the ceramic industry in Foshan has accelerated continuously, entering the stages of scale and industrialization. A considerable number of highly competitive enterprises have emerged throughout the industry's supply chain.

In the field of ceramic machinery, KEDA Industrial Group stands out as a leader.

KEDA Industrial Group is a typical coastal private manufacturing enterprise that has achieved a leading position in its niche field. It epitomizes the transformation from localization to global competitiveness. Behind the ascent of Chinese ceramic machinery enterprises onto the world stage, KEDA Industrial Group's 31 years of continuous and forward-looking exploration in the ceramic machinery business within the industry plays a crucial role.

Take a Two-pronged Approach, Aiming for the Global Market

In the early days, Chinese enterprises were not prominent on the world stage, often overlooked.

In September 1999, KEDA Industrial Group participated in its first overseas exhibition. With no prior experience, the founders of KEDA Industrial Group were personally involved in machinery loading, transportation, booth construction, and exhibition arrangements. On the first day of the exhibition, September 28th, while founder Mr. Qin LU and others were waiting in line for a taxi, they were facing the entrance of the exhibition hall. To their surprise, among the various national flags displayed, there was no Chinese flag.

The next day, they directly approached the organizers with an interpreter to address the absence of the Chinese flag. After discussions, the Chinese flag was quickly raised in front of the exhibition hall. This marks the formal entry of Chinese ceramic machinery products onto the world stage, signaling a crucial step for Chinese companies to compete on equal footing with overseas competitors.

Building on the initial exploration of overseas markets, KEDA Industrial Group officially adopted a "two-pronged" strategy in 2008, targeting both Chinese and international markets, gradually transitioning from exporting single machines to complete production lines. Leveraging the competitive advantages of high cost-effectiveness and durability, the company gradually penetrated markets in Southeast Asia, South Asia, the Middle East, and other regions.

"Going abroad initially means internationalization, and the second step after internationalization is globalization." Mr. Xuexian YANG, the General Manager of KEDA Industrial Group, is well aware of the company's development direction. "The earliest form of internationalization is to sell products to various places around the world. Globalization, on the other hand, means producing globally, providing local services, and even having employees regardless of nationality"

The first overseas subsidiary of KEDA Industrial Group was established in India. "After relatively successful operations, we began to delve into more in-depth global layouts," says Mr. Xuexian YANG.

In 2017, KEDA Industrial Group's second overseas subsidiary was established in Turkey, a crucial part of KEDA's overseas business development. Mr. Xuexian YANG pointed out that Turkey is a rapidly developing and prosperous country in the Middle East, with well-developed ceramic and stone manufacturing industries, ranking among the top 10 globally in the ceramic industry.

Due to Turkey's unique geographical location, it has become a "transit station" for KEDA Industrial Group to enter the European market. Turkey is located on the Mediterranean, in the Middle East, facing North Africa, and also backing onto Europe. It has very convenient trade between Europe and North Africa. The Middle East is a traditional ceramic production base, and considering that Turkey is a central location in that area, we can collaborate on business synergies with our enterprises in Europe, radiating outward from this center," says Xuexian YANG.

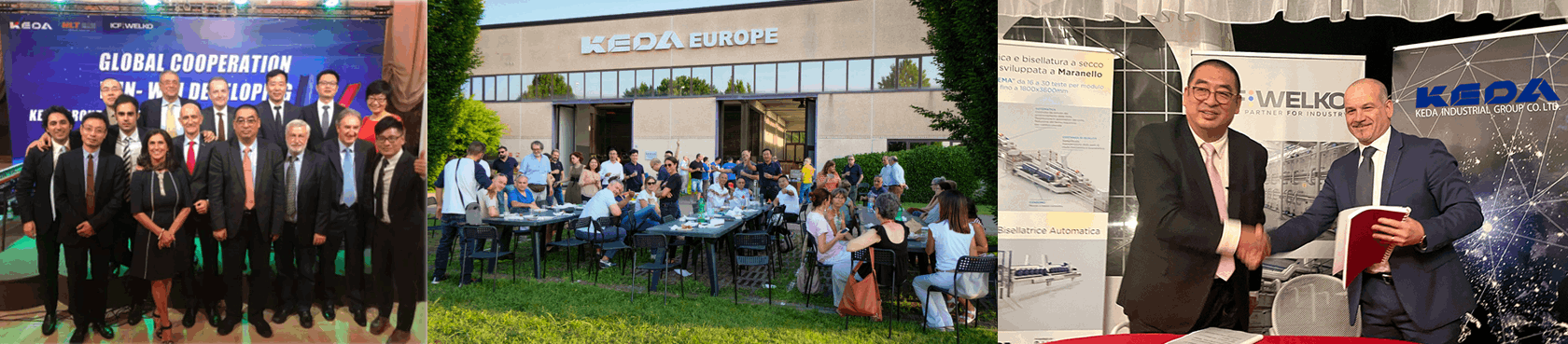

In 2018, KEDA Industrial Group officially announced the acquisition of a 60% stake in the well-established Italian ceramic machinery company, ICF & Welko. The following year, KEDA Industrial Group's third overseas subsidiary was established in Italy, and KEDA Europe was officially formed.

With the European layout basically in place, KEDA shifted its focus to the previously weaker high-end markets in Europe and the Americas.

To further establish a presence in Italy and advance into the European ceramic market, the new "ICF & Welko" under the control of KEDA Industrial Group integrates the advantages of Chinese and European styles. While retaining the advantages of low cost, high output, and high customization, it incorporates original European-style features of high quality and intelligence. This forms the "KEDA Style", leading the world in ceramic tile production.

In September of this year, KEDA Industrial Group expanded its European market layout once again by acquiring a 70% stake in F.D.S. Ettmar S.r.l., a European ceramic mold manufacturing company. It is reported that after this acquisition, KEDA Industrial Group, through the coordination of ICF & Welko and FDS's business, will help expand the European ceramic machinery market and strengthen the overall business segment's profitability.

As time has progressed, KEDA Industrial Group has established its presence on every continent globally, with businesses reaching markets worldwide. In addition to the aforementioned overseas subsidiaries, KEDA Industrial Group also has plans for expansion in Indonesia and Brazil. Indonesia, with a population of 200 million, is a major ceramic production country. Mr. Xuexian YANG predicts that Indonesia's relocation plan will generate a considerable demand. Brazil, as the core of South America, is the world's third-largest producer of architectural ceramics. By establishing a presence in South America and radiating to North America, KEDA Industrial Group aims to meet the considerations of globalization.

"All these points are made based on considerations of globalization," says Mr. Xuexian YANG. "Thirty or forty years ago, many European companies opened businesses in China to gain market share. Today, we need to open businesses locally, and in the future, to occupy more local market share, we need to operate the local market with a localized management mindset."

However, the ceiling for the ceramic machinery business has also emerged.

Deepen Global Thinking, Creating the Second Growth Curve

"KEDA's main business is ceramic machinery, but ceramic machinery also faces a problem: a low ceiling. It is a very small niche industry that faces issues of the scale and plasticity of enterprise development. For example, achieving the top position in Chinese ceramic machinery, then becoming the top in Asia, and reaching such a large scale only results in an income of RMB 5 to 6 billion. But I believe this is not the goal of many KEDA members; they hope to make KEDA bigger and set higher goals, which requires exploring new businesses." Mr. Yuejin LI, the Secretary of the Board of Directors at KEDA Industrial Group, pointed out the ceiling limitation of the single ceramic machinery business to The Time Weekly reporters.

In fact, KEDA Industrial Group has been exploring the second growth curve since 2012, experiencing some setbacks. "The challenge for KEDA lies in transformation, finding a stable industry, and extending from the ceramic industry is the safest option," said Mr. Yuejin LI. He had also pondered the issue of KEDA Industrial Group's development of the second growth curve. Building materials are KEDA's most confident business, and based on previous overseas experience, Africa, with relatively backward urbanization, presented a good opportunity.

In 2015, KEDA Industrial Group conducted research on the African architectural ceramic market in collaboration with Guangzhou SUNDA International Group, one of the earliest Chinese international traders to enter Africa. In December, the two parties reached a preliminary cooperation framework agreement to jointly build an architectural ceramic factory project in Kenya, Ghana, and Tanzania. In 2016, KEDA Industrial Group's first ceramic factory in Africa, the Kenya Ceramic Factory, started construction.

However, building a modern factory on barren land is not easy.

The site of the Kenya Ceramic Factory was originally a grassland with no access to water or electricity. To complete the ceramic factory, KEDA Industrial Group needed to drill wells at a water source 13 kilometers away and pipe the water into the factory. Furthermore, they had to set up transformers to bring in electricity to solve the water and electricity issues.

In addition, KEDA Industrial Group had to face different legal systems and cultural differences. "Cross-border operations must deal with local legal, economic, and labor environments, especially the differences in employee races, which pose a significant challenge to the operation of the enterprise," said Mr. Yuejin LI. "In the beginning, we occasionally encountered unexpected events, ranging from energy conservation and emission reduction, community development to women's rights, and labor protection. But after these years of growth, we now handle these issues with ease."

Even in the face of numerous operational challenges, the Kenya Ceramic Factory still achieved the goal of construction, production, and profitability in the same year.

The expansion of the African building materials business has opened up a second growth curve for KEDA Industrial Group. As of the end of September 2023, KEDA Industrial Group and its strategic partners have jointly constructed and operated 6 production bases in 5 African countries: Kenya, Ghana, Tanzania, Senegal, and Zambia. They have completed 17 architectural ceramic production lines and 1 sanitary ware production line, with products exported to various countries, including Uganda, Rwanda, Togo, and Benin in East and West Africa.

From Internationalization to Globalization, Creating a New Benchmark for Chinese Enterprises Going Global

Building on the successful implementation of the early "two-pronged" strategy and the exploration of the second growth curve, KEDA Industrial Group's development path has gradually shifted from internationalization to globalization.

The key to becoming a globalized enterprise is the ability to manufacture and provide services promptly in the locations where the business operates. According to Mr. Xuexian YANG, KEDA Industrial Group has established subsidiaries in many countries, although some do not yet have on-site companies. "We have accumulated experience in both developing and developed countries, and we will move more quickly towards globalization in the future."

One crucial aspect of global development is localization.

As KEDA Industrial Group expands globally, the composition of employees in overseas companies is gradually tilting towards localization in addition to establishing production bases locally. According to the introduction, the Indian subsidiary, operating for many years, is primarily composed of local employees. After the acquisition, the workforce structure of the Italian company, ICF & Welko, is 100% local. Similarly, the ceramic factories in Africa have over 90% of their employees being locals.

"By designing great systems, planning, and finding great operational teams, complete localization can be achieved," explained Mr. Xuexian YANG, sharing the experience of localizing overseas subsidiaries. It is understood that the development process of KEDA's localization in Africa is divided into three stages: the first stage involves sending Chinese employees to establish factories and supply chains locally; the second stage includes training local employees from the most basic operational positions, gradually deploying trained employees to new factories; and the third stage involves gradually promoting local employees to middle and even high-level management positions.

Mr. Yuejin LI stated that having local employees as department heads in middle management is not a problem, and there are many local master's and doctoral graduates. "Of course, the salaries we offer locally are more than 20% higher than those of normal local enterprises," he added.

With the deepening expansion of KEDA's "globalization" strategy, the company has established bases in Italy, India, and Turkey. Its ceramic machinery business covers more than 50 countries and regions, including India, Bangladesh, Pakistan, Southeast Asia, Africa, Europe, North America, and South America, demonstrating a robust global supply and service capability.

In terms of the building materials business, one of the subsidiaries of KEDA Industrial Group, Twyford International has become a leading supplier of architectural ceramics in Africa. It has successively deployed production capacities in countries along the East and West African lines, as well as key countries in central and southern Africa. In 2022, it ranked ninth among the top 30 global ceramic tile producers. Furthermore, Twyford International has established a presence in local resources, markets, and manpower. By adopting a localized business strategy and after years of deep cultivation, the company has built advantages in channels, costs, and more, resulting in a satisfactory return on investment.

Bolstered by its experience in localization, KEDA Industrial Group's overseas business development has become increasingly smooth. In the first three quarters of 2023, the company's revenue reached RMB 7.028 billion, with over 60% coming from overseas.

In addition, KEDA Industrial Group actively fulfills its corporate social responsibility during its overseas development, demonstrating the responsibility of a major Chinese enterprise.

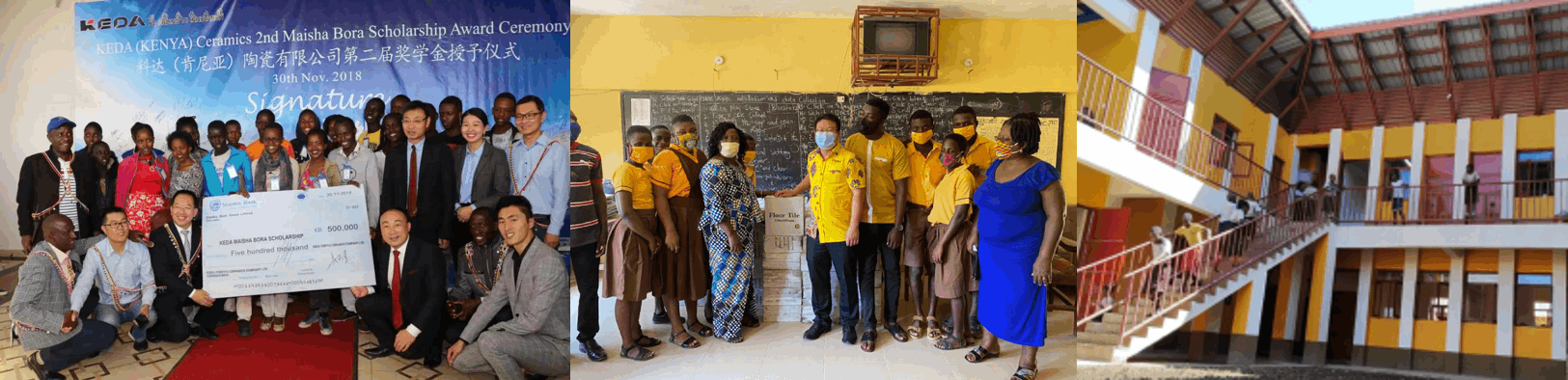

Starting in 2017, KEDA Industrial Group established the KEDA Maisha Bora (local language, meaning "better life") scholarship, aiming to assist students in the Kajiado region who are outstanding in both academics and character but face financial difficulties. In 2018, the company donated a KEDA DBSA SCHOOL (Chinese name: KEDA Dream Making School) to Mathare 4A, the second-largest slum in Kenya. The school covers an area of 360 square meters and can accommodate 430 students simultaneously. In 2019, KEDA invested in building the "Spring of Friendship" for the local Maasai people, greatly improving the water supply problem that had remained unresolved in the region for decades.

Due to the high recognition of KEDA Industrial Group's business and social and humanitarian aspects, following the USD 165 million funding support in 2020, the International Finance Corporation (IFC) has once again provided EUR 200 million in long-term funding support in 2023, with the loan amount significantly exceeding the previous period. This significantly surpasses the previous amount and not only signifies the company's growing influence in overseas financial institutions and markets but also contributes to optimizing the financing structure, reducing financing costs, and supporting the steady progress of the company's "globalization" strategy.

Today, with its increasingly mature global development experience, KEDA Industrial Group is rapidly expanding its market in various countries and regions worldwide.

Looking to the future, building on the upgraded "roadmap" for development, the company has proposed strategies such as "Ten Billion Ceramic Machinery" and "Ten Billion Building Materials". The company aims to become an all-encompassing ceramic machinery service provider, create an African building materials group, expand its global sales network and localization, diversify and enrich product categories, promote the company's business performance, and contribute to the realization of its global enterprise goals.

Looking ahead, KEDA Industrial Group, based on its "globalization strategy", will drive long-term development in "Globalization, Servitization, Digitalization, and Youngization". Aligned with the international energy reform trend, the company will advance towards higher goals, consistently create value for customers, shareholders, employees, and society, and make happiness last longer!

(Shared from The Time Weekly)

loading...

loading... 21 Dec 2023

21 Dec 2023