Left: Customer workshop manager (left) praises the first locally modified and refurbished polishing machine completed by KEDA India's Indian employees, witnessed by Nikunj.M, Deputy Manager of KEDA India's Production Department (right).

Right: The first polishing machine independently modified and refurbished by Indian employees of KEDA India makes its debut

Right: The first polishing machine independently modified and refurbished by Indian employees of KEDA India makes its debut

Much like any ordinary morning, it was destined to be extraordinarily significant. When faced with two old polishing machines placed in front of them, the Indian employees of KEDA India might not have realized that this moment would not only be a turning point in their careers but also mark a new beginning for KEDA India's "Localization" efforts.

The outdated appearance of these two old polishing machines, covered in rust and corrosion, seemed to have lost their vitality due to the passage of time. However, the management team and Indian employees of KEDA India saw the opportunity to explore new markets and expand their business. The Indian team worked tirelessly and persevered to successfully modify and refurbish the equipment, eventually achieving a successful sale.

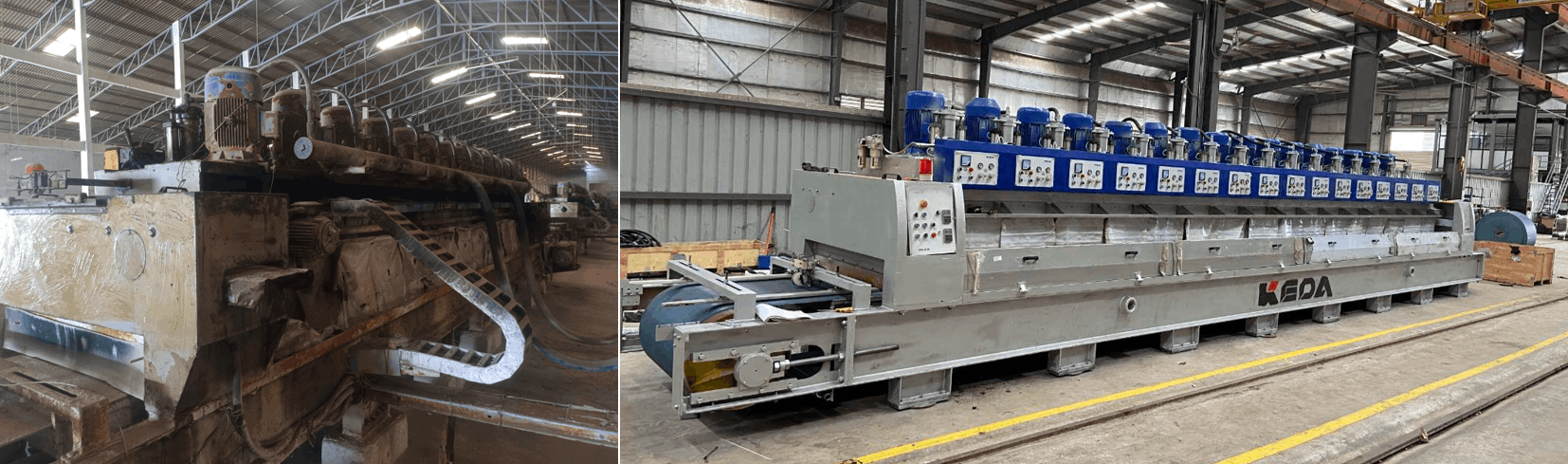

Left: The old, unrefurbished polishing machine before modification

Right: The refurbished polishing machine after cleaning and renovation

Right: The refurbished polishing machine after cleaning and renovation

On September 1, 2018, KEDA India launched its first modified polishing equipment, but it was completed under the guidance of Chinese technicians. The COVID-19 pandemic extended its reach over a span of three years, as all Chinese technical personnel had to return to China, resulting in a complete suspension of modification operations for a full three years.

Currently, due to the difficulties in obtaining visas to India, there are no Chinese technical personnel on-site at KEDA India to provide direct guidance. Guidance and advice from Chinese technical personnel can only be provided through video conferencing. This transition from non-existence to fruition presented unprecedented challenges for KEDA India's Indian employees. Meanwhile, KEDA India's Indian management team recognized this as an excellent opportunity to deepen their commitment to localization. Under the coordinated decision-making of the management team, KEDA India quickly formed a united and collaborative local Indian team. Amidst formidable challenges, the project was officially launched.

Each day, members of the local Indian project team collaborated hand in hand to overcome obstacles. Despite facing numerous difficulties during the restoration process, they remained undaunted. On those long nights, under the workshop's illumination, they meticulously repaired each component of the machines. The Chinese and Indian teams on either side of the video call generously shared their experiences and discoveries, forging a tight-knit collaborative relationship that streamlined the entire modification process.

The modification and refurbishment team from KEDA India's production department

After two months of strenuous effort, the first polishing machine, symbolizing further progress in the "Localization" journey, was finally unveiled by the Indian employees themselves. However, this did not mark the end of the project. To truly rejuvenate this polishing machine, the entire team continued to invest more time and effort, conducting a comprehensive cleaning and refurbishment to enhance its aesthetics.

Following meticulous preparation and precise arrangements, the refurbished polishing machine was successfully loaded and dispatched to the customer's factory. This was not merely a product shipment; it was the embodiment of quality and professionalism.

Left: Complete shipping of the polishing machine after modification

Right: The polishing machine, modified and refurbished, was successfully commissioned at the customer's site

Upon arrival at the customer's site, the machine was installed and commenced operation smoothly on the same day, yielding outstanding results. The commissioning process was exhilarating, with the equipment running smoothly and everything in perfect order. The modified polishing machine not only resolved previous issues but also exhibited a significant enhancement in performance, marking the successful completion of this modification project!Right: The polishing machine, modified and refurbished, was successfully commissioned at the customer's site

On the first day of production started, customer satisfaction was self-evident. The customers effusively praised the production results achieved by this modified polishing machine, with unanimous approval as they wholeheartedly raised their thumbs in commendation. An enthusiastic customer representative exclaimed, "The restoration and commissioning of the polishing machine have yielded unexpected results. The machine looks brand new after modification! We are highly satisfied with the performance and quality of KEDA's products!"

The path to 'localization' manufacturing by KEDA India is both challenging and lengthy. In the days that lie ahead, the KEDA India team will undeniably maintain their fervent enthusiasm. Together with their customers, they will embrace numerous challenges and opportunities, providing superior products and services, thus co-authoring a more splendid chapter in their collaborative partnership!

(Wenqi WANG, KEDA India)

loading...

loading... 25 Aug 2023

25 Aug 2023