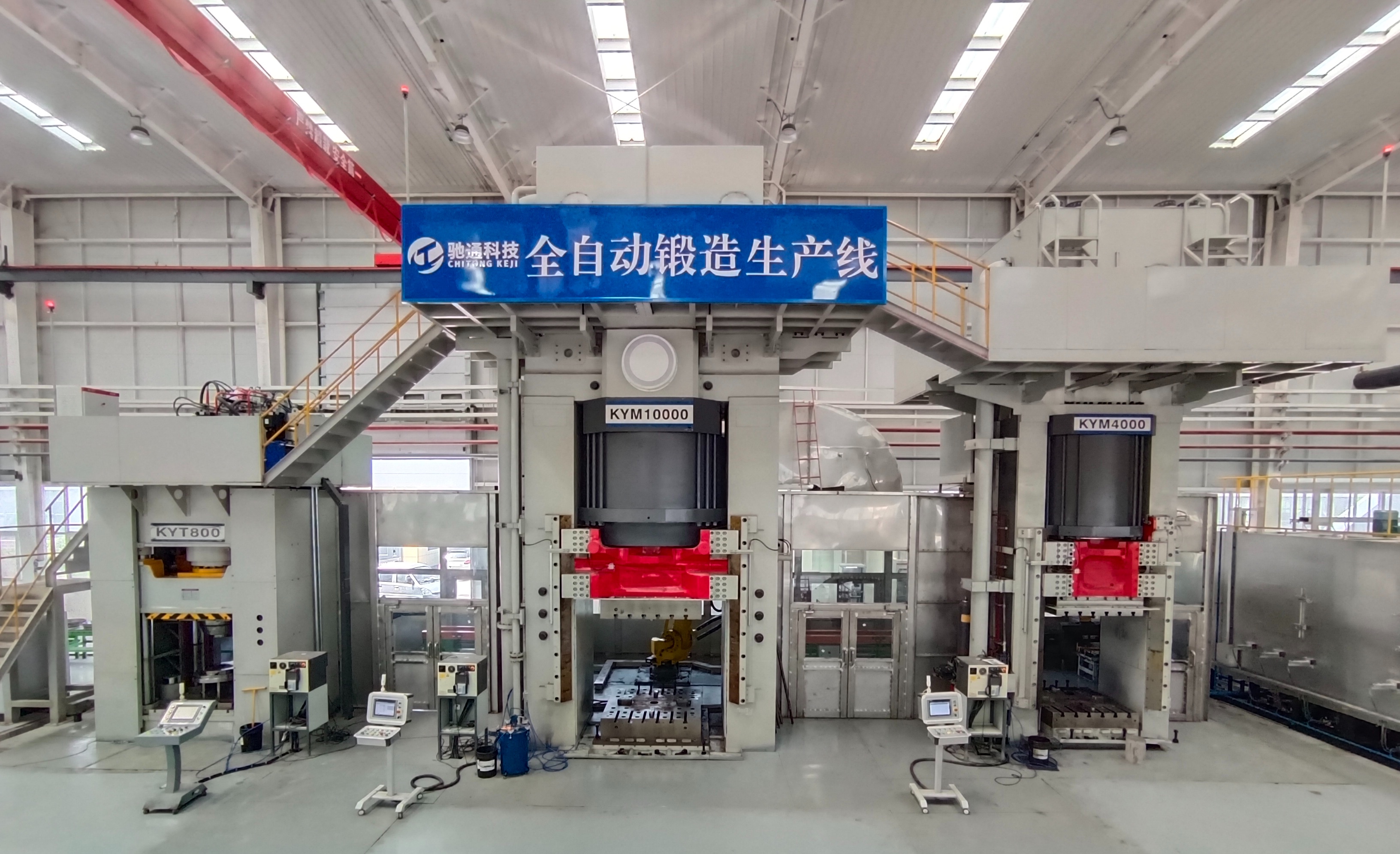

Recently, the automated aluminum-alloy wheel hub forging production line built by KEDA Ceramic Machinery for Henan Chitong Technology Co., Ltd. achieved successful trial production. This milestone marks the transition of KEDA Ceramic Machinery's independently developed KYM series wheel hub forging presses into mass production. It also represents a major step forward for Henan Chitong in the field of high-end intelligent wheel hub manufacturing.

The fully automated forging production line incorporates 3 KEDA presses: KYM4000 forging press for pre-forging, KYM10000 forging press for final forming, and KYM800-ton press for punching and hole expansion.

These presses integrate advanced technologies such as a wound-type frame structure, integrated cylinder design, high-strength heat-resistant composite bolster plates, and X-type planar guiding system. The entire series adopts electro-hydraulic servo control systems, offering outstanding stability, high precision, energy efficiency, and excellent cost performance.

Since its debut in 2017, KEDA Ceramic Machinery's aluminum-alloy wheel hub forging press has continuously evolved through innovation driven by customer needs. The product line has expanded to include models with capacities of 4,000 tons, 6,000 tons, 8,000 tons, 10,000 tons, and 12,500 tons, covering a full range of wheel hub sizes and forging requirements across the market.

(KEDA Ceramic Machinery)

loading...

loading... 28 Jul 2025

28 Jul 2025