Just like individuals, enterprises must maintain excellent quality as their foundation while also adapting and seizing opportunities as they arise. Every transformation is aimed at becoming better and striving towards higher goals.

As one of the longest-standing enterprises in China's ceramic machinery industry, HLT celebrates its 67th anniversary this year. Over several decades of development, values such as pragmatism, stability, integrity, unity, and progressiveness have become ingrained in the company's DNA.

These values serve as the foundation for embracing and driving forward the two significant transformations of HLT&DLT in the past, acting as the cornerstone of "harmony among people" within the company.

Mr. Xuexian YANG, Managing Director of KEDA Industrial Group and General Manager of HLT&DLT, pointed out that the two strategic adjustments, "focusing on presses" in 1998 and "press diversification and ceramic machinery serialization" in 2013, enabled HLT&DLT to seize the dividends of the times.

In 2024, both Chinese and international ceramic enterprises are increasingly inclined towards requiring a single ceramic machinery enterprise to offer complete production lines. In this "complete production line era", how can the goal of "ensuring product quality while reducing costs for customers, and efficiently and flexibly responding to customer needs" be achieved?

To address this, HLT&DLT has undergone another transformation, presenting the main feature of "independent production and combined sales". Mr. Xuexian YANG expressed that this is the "biggest change" for HLT&DLT in the past 11 years.

▲Mr. Xuexian YANG, Managing Director of KEDA Industrial Group and General Manager of HLT&DLT

In 1998 | Major Transformation One

Focusing on Presses, with a Market Share Exceeding 70%

HLT's origins trace back to the establishment of the Foshan Shiwan Hardware Machinery Repair Factory in 1957. Subsequently, it underwent several name changes, evolving from the "China State-owned Shiwan Ceramic Machinery Factory" to the "Foshan Ceramic Machinery Manufacturing General Factory of Foshan Ceramic Industry and Trade Group Company" and later the "Guangdong Fotao Group HLT&DLT Machinery Co., Ltd."

Today, it operates primarily under the name "HLT Industry Co., Ltd.", serving as a leading supplier of ceramic machinery complete production lines.

Throughout HLT's development journey, its transformation into a complete production line supplier is evident. Prior to its pivotal "Focus on Pressing Machines" transformation in 1998, HLT had already accumulated 41 years of research and production experience in various ceramic machinery, including pan mills, mixers, filter presses, diaphragm pumps, magnetic separators, feeders, pug mills, ball mills, spray towers, presses, and kilns.

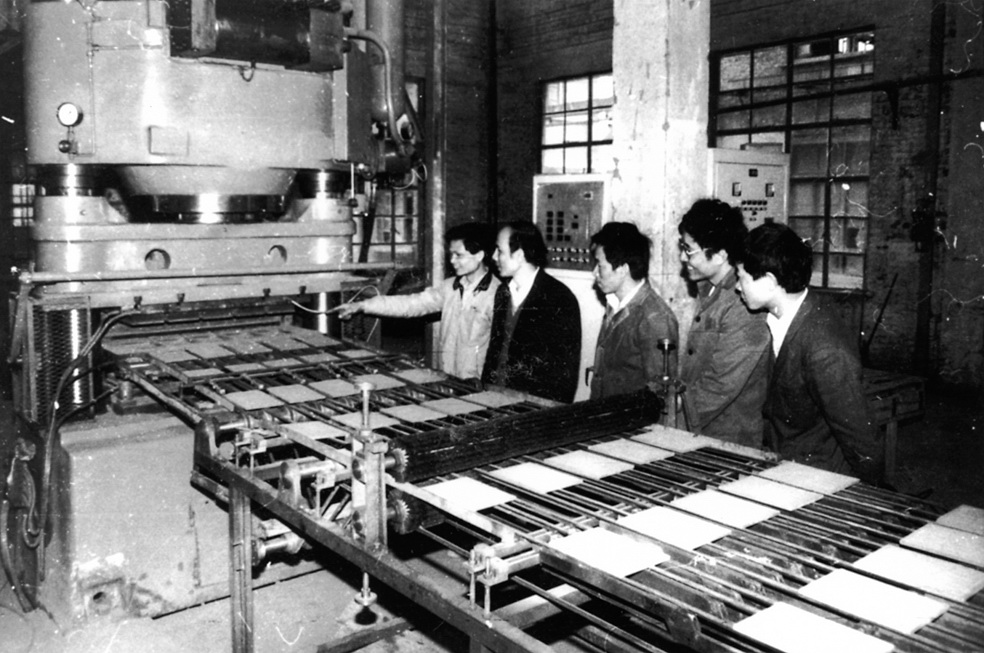

The pivotal shift towards pressing machines occurred in 1985 when the Chinese government initiated the "China Torch Program" for the development of automatic ceramic tile presses, assigning the project to the China State-owned Shiwan Ceramic Machinery Factory. This initiative was one of the key research projects under China's "Seventh Five-Year Plan".

In 1988, the inaugural ceramic automatic tile press YP600 was successfully developed in China. That year, at the Foshan Shiwan Building Ceramics Factory, the inaugural batch of 150×200mm colored glazed tiles was successfully pressed, marking the conclusion of China's reliance on imported automated production lines for colored glazed tiles.

▲ The YP600 automatic hydraulic press pressed the first batch of colored glazed tiles at

the Shiwan Building Ceramics Factory on December 25th, 1988.

the Shiwan Building Ceramics Factory on December 25th, 1988.

Fast forward to 1998, an increasing number of private enterprises entered the ceramic machinery sector, intensifying competition. In order to maintain a competitive edge, Mr. Guoxing YAN, then Chairman of HLT&DLT, initiated a strategic overhaul termed "comprehensive focus on presses", recognizing the high technological and manufacturing thresholds associated with presses.

The efficacy of this transformation proved remarkable. In 1999, press sales exceeded 100 units, heralding a new era of Chinese press marketization. In 2003 and 2007, sales further surged to surpass 200 and 400 units respectively. Particularly noteworthy is the zenith reached in 2010 with 719 units sold and sales performance surpassing the RMB 1 billion mark.

▲ Press production workshop

Mr. Xuexian YANG regards these significant figures with particular reverence. He emphasizes that in the singular domain of ceramic presses, HLT's market share peaked at over 70%. Their shipment volume consistently maintained a leading position globally, attributable to the strategic dividends yielded by the "comprehensive focus on presses" initiative.

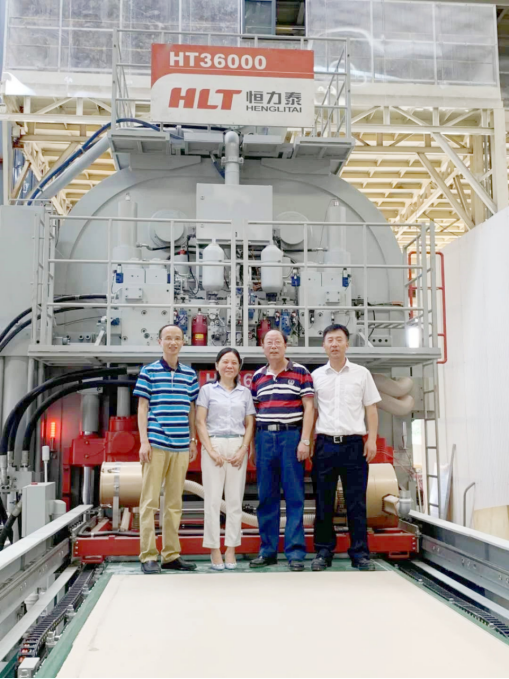

As of now, HLT's tile presses have evolved into a product series covering over 40 specifications ranging from 600 to 36,000 tons, forming what is renowned as the "press supermarket".

▲ In 2019, the HLT HT36000 press successfully produced the first piece of 1600×3600mm ceramic sintered stone

at the Xiqiao production base of the Monalisa Group.

at the Xiqiao production base of the Monalisa Group.

In 2013 | Major Transformation Two

Press Diversification and Ceramic Machinery Serialization

Around 2012, both in China and internationally, particularly among international customers, there was a burgeoning demand for ceramic machinery enterprises capable of providing complete production lines. Leveraging its DNA and advantages steeped in complete production lines, HLT strategically embarked on accommodating this demand.

During this period, HLT had just completed a strategic reorganization with KEDA Industrial Group, enabling both industry leaders to jointly tackle international market competition, thereby significantly fostering the industry's healthy development.

Mr. Xuexian YANG, who had already devoted 20 years to HLT, was appointed as the General Manager. Under the guidance of KEDA Industrial Group's Chairman, Mr. Cheng BIAN, Mr. YANG spearheaded the strategic transformation titled "press diversification and ceramic machinery serialization" in 2013.

Press diversification involved transcending the boundaries of ceramic presses to encompass all industries requiring such machinery. From the debut of the first refractory material press in 2015, to the subsequent introduction of permeable tile presses, wall material presses, and, post-2020, venturing into aluminum extrusion presses and lithium-ion battery presses...

▲ The YPR2500 automatic hydraulic press for refractory tile

Drawing upon decades of accumulated research achievements, talent reserves, and technical expertise, HLT&DLT has gradually solidified its position in numerous press fields, even attaining a leading status. Mr. Xuexian YANG proudly declares that in domains such as refractory material presses and aluminum extrusion presses, HLT&DLT currently holds a leading position.

▲ The YPL2000 aluminum extrusion press

Ceramic machinery serialization is indeed the inevitable path to meeting the demand for ceramic complete plant projects. It all began with the acquisition of ceramic raw material machinery company Zhuodahao Machinery in 2014 (now evolved into HLT Technology). Subsequently, in 2016, DLT Technology was established, focusing on ceramic kilns.

In recent years, there has been the establishment of HLT Ceramic Technologies, specializing in ceramic machinery spare parts, consumables, and technical services, along with the newly added After Kiln Division.

With these developments, from raw materials to presses, from kilns to after-kiln processes, including ceramic machinery spare parts, consumables, and technical services, a grand layout has been completed for a company to provide ceramic complete plant projects, collectively referred to as "HLT&DLT".

However, new challenges have emerged. As the company expands, its product lines lengthen, and its workforce grows, how can it prevent the emergence of "Big Company Disease" such as weak cost awareness, multiple leadership structures, and slow decision-making?

In 2024 | Major Transformation Three

Independent Production and Combined Sales

On October 30th, 2023, HLT&DLT held its inaugural integration conference and officially established the latest organizational structure by the end of the year.

Starting from January 1st, 2024, HLT&DLT officially operates with a new structure comprising 7 product divisions (business segments), 3 marketing segments, and 6 functional departments. These changes represent what Mr. Xuexian YANG refers to as the "greatest change" in HLT&DLT in the past 11 years.

The 7 product divisions include the Extrusion Press Division, Ceramic Press Division, HLT Technology Company (Raw Material Machinery), DLT Technology Company (Kilns), HLT Ceramic Technologies Company (International Ceramic Machinery Parts, Consumables, and Technical Services), Parts Division, and After Kiln Division.

The 3 marketing segments consist of Chinese Marketing Division 1, Chinese Marketing Division 2, and International Marketing Center.

The 6 functional departments comprise General Management Office, Lean Management Office, Finance Department, IT Department, Human Resources Department, and Administrative Department, which provide comprehensive support to the product divisions and marketing segments.

Thanks to HLT's pragmatic, united, and enterprising corporate genes cultivated over nearly 70 years, Mr. Xuexian YANG pointed out that this transformation encountered almost no resistance, completing a smooth transition in just two months.

The proactive drive for change in HLT&DLT is also spurred by KEDA Industrial Group. In recent years, after adjusting its organizational structure, KEDA's reputation and market share have steadily improved, arousing a sense of crisis within HLT&DLT.

Regarding their relationship, Mr. Xuexian YANG emphasized that although they are "two brothers", they engage in free competition because only through competition can they continue to progress.

So, what are the differences between the current structure of HLT&DLT with its 7 product divisions, 3 marketing segments, and 6 functional departments compared to before?

In response, Mr. Xuexian YANG pointed out that each division continues to operate independently. However, unlike before, divisional managers are now not only responsible for production but also accountable for business results, namely, profitability.

In the marketing segments, the most significant change is that sales personnel no longer only sell individual products but instead sell complete production line products.

As a result, on the production end, not only have they achieved specialization, efficiency, and improved product quality with shorter delivery cycles, but they have also achieved flexibility and standardization, lower production costs, and faster after-sales service.

On the customer end, the reduced costs can be passed on to customers as benefits. Furthermore, customers now only need to liaise with a single sales representative to purchase the complete production line of HLT&DLT, significantly reducing communication costs.

Currently, the demand for a single ceramic machinery enterprise to provide complete production line solutions is not only robust among international customers but also increasingly evident among Chinese customers.

The recent transformation of HLT&DLT, characterized by "independent production and combined sales", once again aligns with the call of the times. Guided by a unified effort from top to bottom, the company steadily advances towards its goal of becoming a leading machinery supplier of ceramic complete plant projects in China and world-class globally.

(CHINA CERAMIC INFORMATION)

loading...

loading... 26 Mar 2024

26 Mar 2024