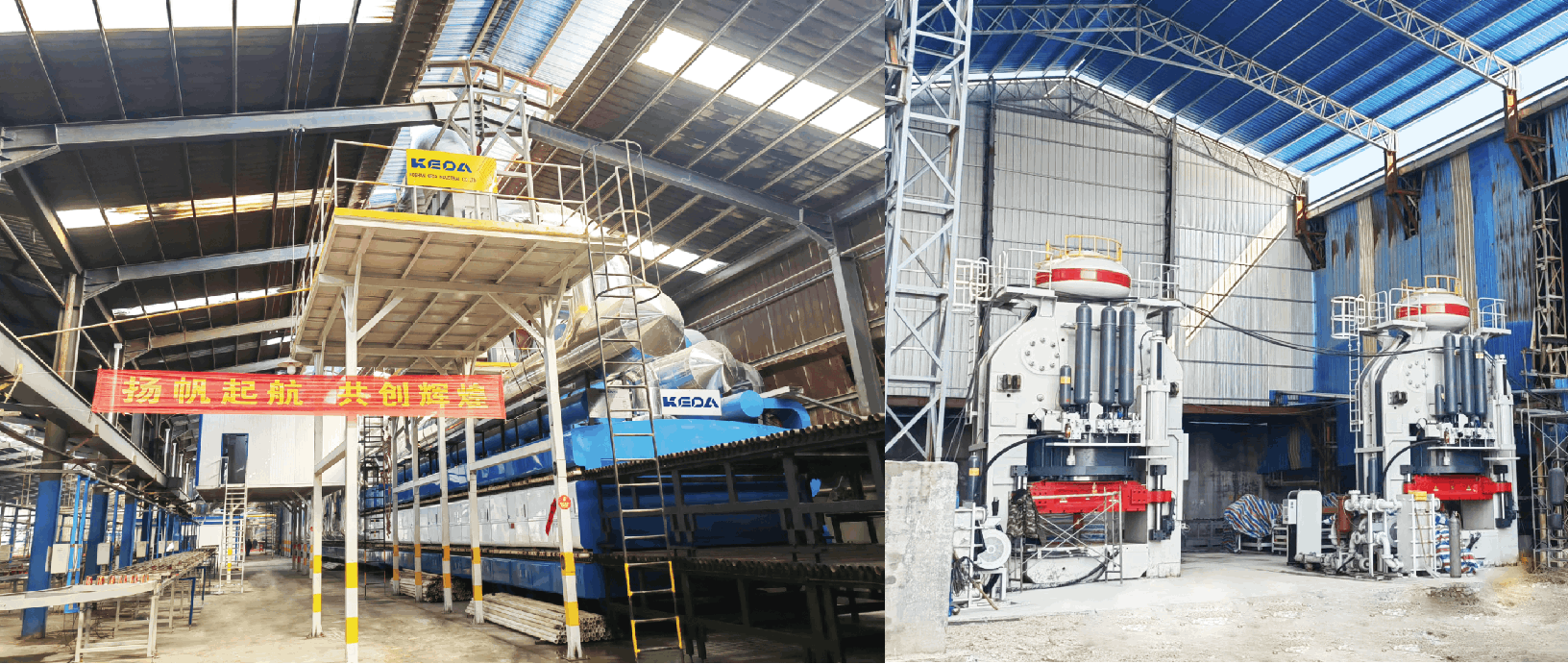

On the eighth day of the Chinese Lunar New Year, prosperity arrives from all directions. At the auspicious hour on the morning of February 17th, Jiaxing Ceramic, a subsidiary of Linyi Jinchang Building Ceramics Co., Ltd. (hereinafter referred to as Jiaxing Ceramic), successfully ignited its medium slab and large slab production lines.

This production line represents Jiaxing Ceramic's second facility, primarily dedicated to manufacturing products with specifications such as 400×800mm, 800×800mm, 600×1200mm, 750×1500mm, and 900×1800mm, boasting a daily output of 45,000㎡.

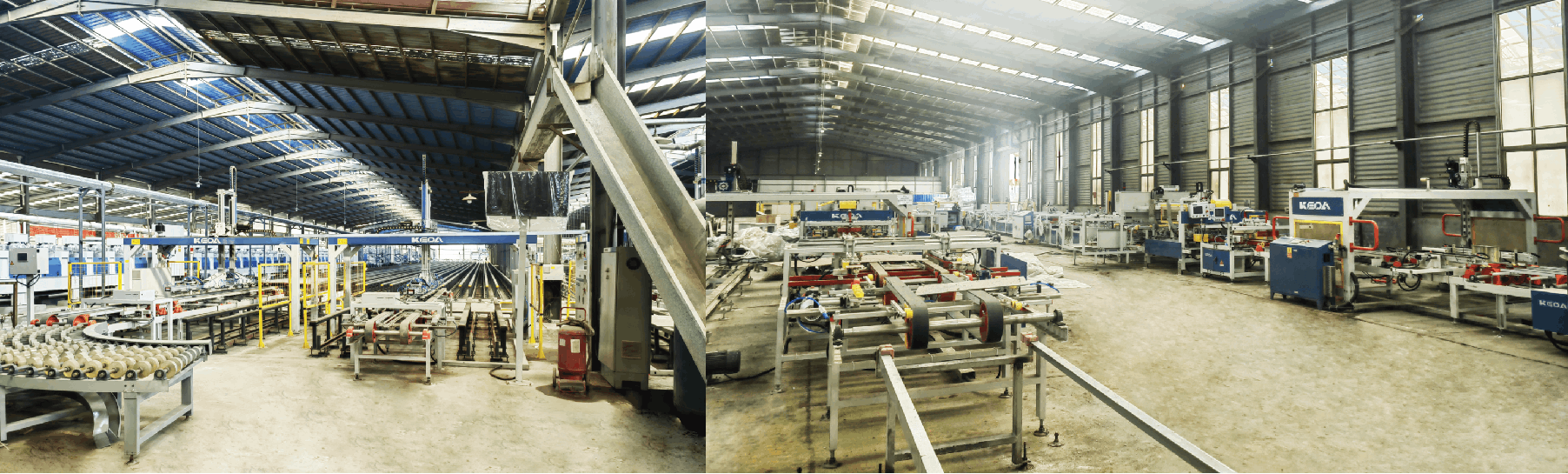

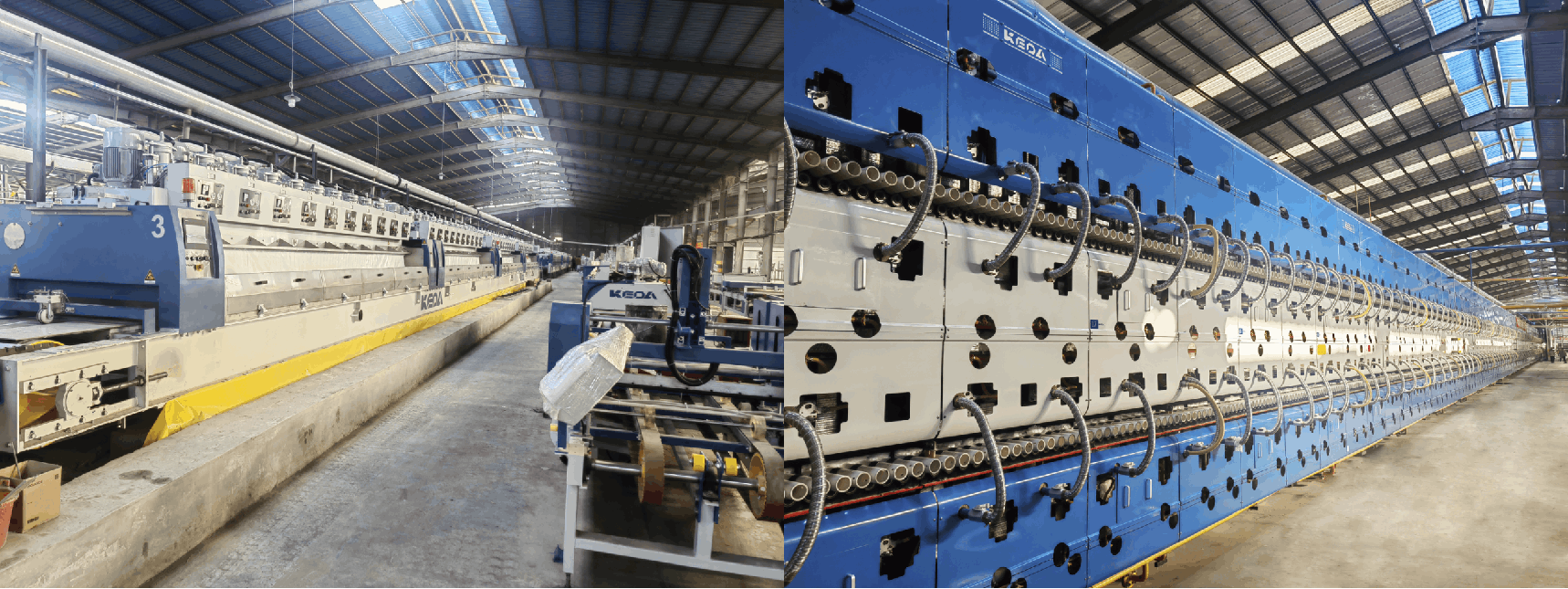

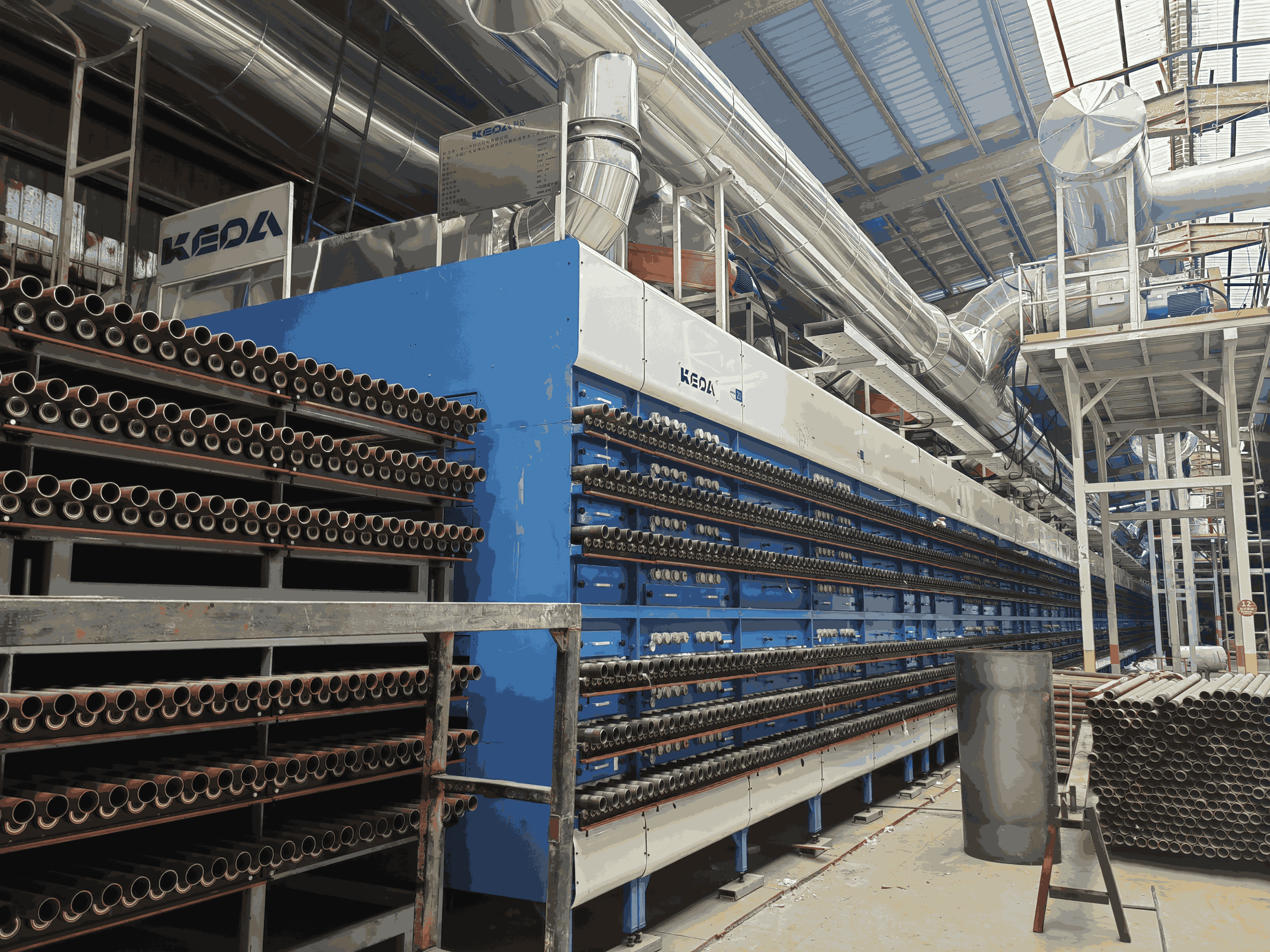

KEDA Ceramic Machinery has tailored a comprehensive set of machinery for the complete production line, which includes the Press KD7818L, highly efficient and energy-saving double-layer roller kiln, six-layer dryer, intelligent tile storage line after kiln, intelligent polishing line, and large slab direct-connected automatic packaging line. This signifies Jiaxing Ceramic's venture into a new era of product enhancement through intelligent manufacturing.

This marks KEDA Ceramic Machinery's second construction of a double-layer kiln in the Linyi production area and the 7th globally, achieving complete coverage of products ranging from internal wall tiles to glazed, medium slabs, large slabs and sintered stones.

KEDA's new generation of highly efficient and energy-saving double-layer kilns empower customers to achieve better superior quality, increased output, reduced energy consumption, and flexible intelligent production, meeting diverse production needs and enhancing their market competitiveness.

Having established a strong presence in the Linyi production area for many years, KEDA Ceramic Machinery resonates with its customers, continuously driving product iteration and technological advancement in the region through innovation.

KEDA has introduced industry-leading innovations such as the industry's first 3.85-meter-wide ultra-wide kiln capable of simultaneously firing 11 pieces of internal wall tiles, the first double-layer kiln capable of simultaneous bisque firing and glaze firing in China, the first KD16008 large-tonnage press in Northern north, the first dual-station high-speed packaging line in Northern China, and the first multi-section smart swing polishing machine in Northern China, all originating from the Linyi production area.

The establishment of KEDA Ceramic Machinery's double-layer kilns in the Linyi production area, along with their successful applications in the markets of Vietnam, Turkey, and South Korea, indicates that KEDA's double-layer kilns have gained significant momentum.

Amidst increasingly stringent environmental and energy assessments in the ceramic industry, mounting pressure on the availability of industrial land, carbon peaking and carbon neutrality goals, and the ceramic industry's phase of adjustment, combined with intensified market competition and a surge in customers' demands for flexible customization, the advantages of double-layer kilns can be further accentuated.

Embracing the auspicious start of the year and the festive atmosphere of the Spring Festival, KEDA Ceramic Machinery maintains its unwavering dedication to meticulously implementing this complete production line project, with the aim of setting a new benchmark for intelligent production lines of double-layer kilns within the production area. Moreover, KEDA steadfastly upholds innovation to empower the high-quality development of the Linyi production area, striving to make even greater contributions.

(KEDA Ceramic Machinery)

loading...

loading... 29 Feb 2024

29 Feb 2024