Nikunj DMAKASANA, known as Nik, a graduate of the School of Engineering and Technology, Gujarat University in India, joined KEDA India in 2018. 2018 was the same year when KEDA India officially commenced its operations. As a significant participant and witness to the growth and development of KEDA India, Nik has seen his own progression along with the company. Starting as a regular conveyor belt splicer when he joined, he has grown to become the deputy manager of the production department. In 2021, he was honored with the title of "Outstanding Employee" by the company. His growth and transformation precisely mirror a microcosm of KEDA India's development.

Diligent and Ambitious: "Globalized" Talent Emerging from the Grassroots

On September 1st, after nearly a month of training and learning at KEDA's Dadu factory in Shunde, Nik flew back to India. Armed with a wealth of "earning outcomes", Nik and his team of Indian talents will shoulder the mission of achieving "Globalization" in production and manufacturing for KEDA India in the future.

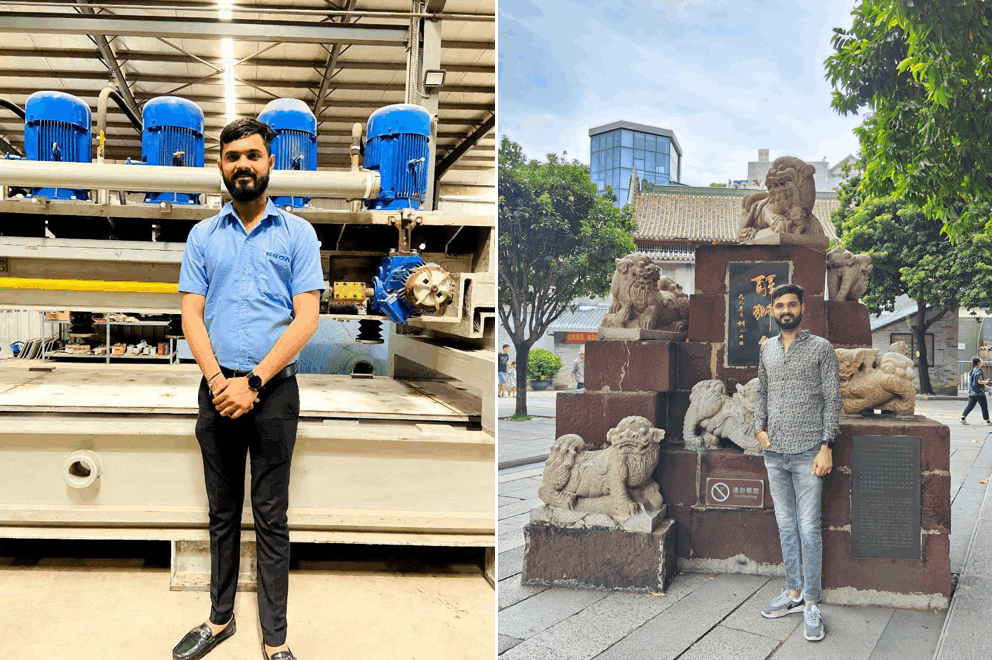

Nikunj DMAKASANA

Nik spent a month training and studying in China, underscoring the high regard and great expectations KEDA India's Chinese management team has for him. As an Indian university graduate, he takes immense pride in working at KEDA. "Even before joining KEDA, I had heard of the name KEDA. Coming from Morbi, located in Gujarat, a traditional ceramic production area in India, I knew that 'KEDA' was a major enterprise in the ceramic machinery industry. After I started working at KEDA, my neighbors couldn't help but say, 'Wow! You work at KEDA, that's amazing!'" Nik shared.

When Nik first joined KEDA, the Chinese masters assigned him to clean the machine. At that time, he didn't quite understand the role, thinking that the job didn't require much technical skill. However, he gradually realized that, for someone like him who had no prior knowledge of ceramic machinery, this was the best way to quickly familiarize himself with the machines and their components. It laid a solid foundation for him to later repair squaring heads for customers, splice belts, and even modify polishing machines.

During the 2-3 challenging years of the COVID-19 pandemic, while KEDA India ensured the safety and protection of all employees, they continued to provide attentive and thoughtful service to customers. Due to Nik's sense of responsibility and dedication, demonstrated during the pandemic, when he fearlessly worked overtime at customers' sites to splice belts, he was promoted to supervisor in 2021. In his personal reflection upon being recognized as an outstanding employee for the year 2021, Nik wrote, "In the past year, I gave 100% to the company, and in the future, I will continue to give more than 100% effort for KEDA. I am fortunate to work at KEDA India!" This genuine love for his work drives him to work even harder, and due to his outstanding performance and high adaptability, he was later promoted to the position of deputy manager of the production department.

Nik Leading the Team on the Production Site

From a grassroots employee to a front-line supervisor and then to a mid-level manager, Nik believes, "Only when everyone gives 100% or even more than 100% effort, can we help the company achieve the best, earn a good reputation, and improve the business. This continual enhancement enables the company to reach new heights, and the employees' sense of happiness will also grow stronger".

KEDA India is in need of numerous "globalized" talents like Nik to grow and rise, supporting the in-depth development of the business.

Rising to Challenges, Leading the Team to Launch the First “Indian Modified” Polishing Machine

Over the three years of the COVID-19 pandemic, Indian local companies have rapidly grown and developed, leveraging the "vacuum advantage" of Chinese companies unable to enter the country. On the other hand, KEDA, benefiting from its forward-looking deployment of a "globalization" strategy, had already acquired land and set up factories locally, employing local staff in India. Even after all Chinese employees left India, the operations continued smoothly, and the company maintained a stable growth trajectory. However, for the long-term development of the enterprise, a deep level of "localization" is becoming an urgent necessity.

Previously, the KEDA India production department was responsible for tasks such as repairing squaring heads and chamfering heads for customers, as well as belt replacements, which were part of component maintenance. The complete modification of the machines was a service conducted by Chinese masters before their departure from India. With the departure of the Chinese masters, this service was temporarily "suspended". It wasn't until November last year, under Nik's leadership, that KEDA India revived this business of complete modification of polishing machines. The local Indian team of 8 individuals, under Nik's guidance, independently completed the modification of the first polishing machine. This marks a significant step for KEDA India in the direction of achieving "globalization" in production and manufacturing!

The First Modified Polishing Machine Completed by Indians

Before the Chinese masters left India, Nik followed them and participated in the modification of several polishing machines. Among the Indian team, he was the only one with such experience. After taking on the responsibility of restarting the complete modification of the machines as arranged by the Chinese management team, he led the team, starting from disassembly, and cleaning, to repair and modification, overcoming multiple challenges step by step. During this period, through video calls on DingTalk, the Chinese team actively provided technical support, enabling the local maintenance team to avoid many detours in India. They completed the repair and refurbishment of the first 16-head polishing machine faster than the set time and produced a total of 3 machines at once.

The customer who purchased the first modified polishing machine witnessed the installation, commissioning, and smooth production of the machine on the same day. They expressed their sincere satisfaction, saying, "The repair and commissioning of the polishing machine have yielded unexpected results. The modified machine looks brand new! We are very satisfied with the performance and quality of KEDA products! We are highly satisfied with the performance and quality of KEDA's products!" This marked a "successful start" for KEDA India's development of complete machine modification. "Providing stable, high-performance, and reliable machinery has always been our direction of effort. This is our consistent commitment to our customers." said Nik, the project leader.

The successful modification of the complete polishing machine not only opens up new markets and broadens the business but also lays a solid foundation in terms of personnel and technology for future localized production of machinery in India.

Nik, entrusted with the responsibility of localized production and manufacturing, also brought back to India the lean production and management philosophy vigorously promoted by KEDA in China during his training there. He aims to promote "globalization" in India.

KEDA's "globalization" is inseparable from deep-rooted "cross-cultural development", and in the future, more and more international talents like Nik will emerge.

(KEDA India)

loading...

loading... 21 Oct 2023

21 Oct 2023