The Enping base of HuaShuo Group covers a relatively large area of approximately 350,000 square meters. And it has complete supporting industries in the surrounding area. The overhaul of the first-phase production line is expected to be completed by the end of August this year. It will establish a large-scale intelligent production line for medium-sized tiles and glazed tiles. After completion, the daily production capacity will be about 100,000 square meters, covering a full range of glazed tile products, including 400x800mm medium-sized tiles, 800x800mm, 600x1200mm, 750x1500mm, and 900x1800mm large-sized glazed tiles. By then, HuaShuo Group will have five major production bases: HuaShuo, Ruixue, Newcene, Pingxiang Huarui, and Enping. With more than 20 production lines and a total annual production capacity of over 190 million square meters, the production scale of HuaShuo Group ranks stably as the third largest in China.

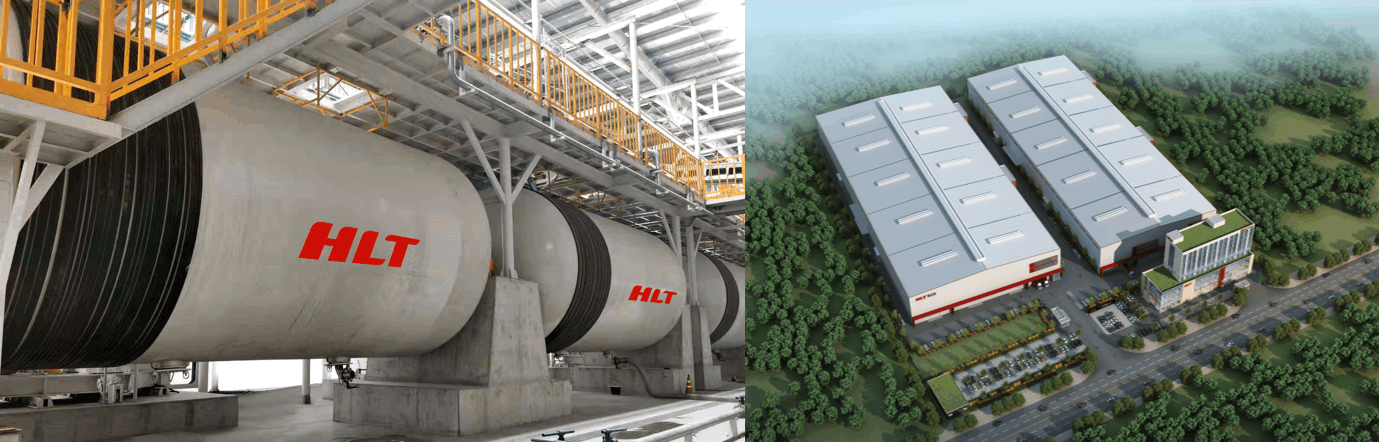

The 100-ton Eco-Friendly and Energy-Saving Ball Mill of HLT Technology

The raw material processing system guarantees successful implementation of the parameters for the front-end manufacturing process. Only great process design and equipment manufacturing can ensure the great performance of the raw materials. The brand-new 100-ton ball mill of HLT Technology is an eco-friendly and energy-saving ball milling system. It was intently developed through the using experience of multiple foreign 100-ton ball mills, the established self-design of ball mills, and years of market feedback.

This 100-ton ball mill is mainly used for intermittent wet grinding of ceramic materials. The main structures, such as the head and the rotary kiln shell, are well-designed and reliable in performance. It adopts a belt reduction structure, with the advantages of a compact overall layout, simple construction, few vulnerable parts, convenient operation, smooth running, and low noise. It also solves technical problems such as low production capacity, high energy consumption, and large pollution in ball milling. In addition, the accumulated production experience and stable production management system of HLT Technology can effectively guarantee product quality and seamless integration with automation and intelligent technology. At the same time, it will bring revolutionary improvements to delicacy management, labor intensity reduction, and labor shortages in ceramic enterprises. Overall, it is a great engineering achievement that significantly improves the single-line production capacity and revitalize the raw material workshop. Furthermore, it provides a solid foundation for the normal and stable operation of subsequent equipment and the completion of mass production in the entire factory.

Advantages:

1. Equipment footprint reduced by 25%

2. Labor intensity reduced by 30%

3. Infrastructure investment cost reduced by 15%

4. High efficiency with a 5% energy consumption reduction

HLT Technology is a wholly-owned subsidiary of HLT Industry, established in December 2021. With high-end intelligent ceramic production line equipment and a comprehensive service system, it has successively launched a series of green, efficient, and energy-saving products, including raw material pre-crushing system, continuous slurry system, ConTinuB continuous pulping system, intelligent large-tonnage intermittent ball mill, FaST series spray pulverizing system, energy-saving hot stove, and fully automatic feeder. It has rapidly established a business network in more than 20 countries and regions. Besides, it has conducted business transactions with many well-known domestic ceramic enterprises such as Monalisa Tiles, Nabel Ceramics, Oceano Ceramics, Newpearl Group, and L&D Ceramics. In the future, HLT Technology will be constantly committed to the development of the ceramic machinery industry with technological innovation, strict standards, and advanced design.

(Huaying HUANG, HLT&DLT)

loading...

loading... 18 Jul 2023

18 Jul 2023