With the theme of "Flexibility Interconnection, Efficiency, Intelligence", KEDA Ceramic Machinery showed global users its latest products and technologies in terms of promoting efficiency improvement, flexible manufacturing, green and low-carbon, as well as digital transformation in the global ceramic industry in Hall 9 and Hall 8.

KEDA Ceramic Machinery is expected to receive more than 500 overseas customers from Vietnam, India, Indonesia, Malaysia, Bangladesh, Turkey, Brazil, Italy, Spain and other regions of the world during the exhibition. When they visited Hall 9 to renew the friendship with KEDA’s staff and witnessed the great changes of KEDA over the years, they were impressed by KEDA’s innovation strength and rapid development and very complimentary about it.

★ Multiple new products debut in the central role, showcasing the strength of KEDA ★

The display and operation of KEDA's latest generation of Extendler continuous forming roller pressing system at KEDA had attracted many customers to stop and watch.

KEDA’s Extender continuous forming roller pressing system has been upgraded and updated twice based on the operation experience in the industry. It is developed according to the powder characteristics and processes of domestic ceramics factories and suitable for the production of large-sized ceramic plates/sintered stone/thin plates; The finished plates has a width of 800-1600mm, a thickness of 3-20mm, and a maximum output of 28500㎡/day. The surface flatness of the shaped tile bodies is ≤ 0.15mm, and the density difference is ≤ 0.06g/cm³. It has advantages of stronger powder adaptability, wider range of water application, higher yield and energy conservation, better forming quality, high flexibility, intelligence and ease of use, as well as an convenient production changeover.

In the after-kiln production line area, KEDA Deep Processing Machinery displayed the multi-stage efficient and intelligent composite swing polishing machine with the brand new industrial design and the second generation CNC intelligent edging machine, which also attracted widespread attention from domestic and foreign customers.

Adopting a new UI design interface, the brand new Engine series multi-stage efficient and intelligent composite swing polishing machine of KEDA is quite user-friendly for operation. The data on the coverage uniformity of grinding head is analyzed through AI simulation technology and a controller is fitted to make the swing frequency of the crossbeam adaptive to the speed of the belt. The lightweight design of the crossbeam assembly and the equipment with a permanent magnet motor make the machine more energy efficient. The control strategy of integrated mathematical model of the grinding head trajectory realizes one key switching between various crossbeam swing modes: cross swing, synchronous swing, sequential swing and combined swing. The new design has reduced the skill requirements for operators, improved polishing efficiency and uniformity significantly, saved electricity consumption and raised product quality. It is the best choice for enterprises to produce high-quality products in a low-carbon and efficient way.

The Engine series second generation CNC intelligent edging machine has further breakthrough and upgrades on the basis of the previous generation. Its integrated AI algorithm technology, automatic distribution of the grinding amount of each grinding head and control of the machining dimensions and diagonal errors solve the size problem of cold engines. The machine is equipped with a DC brushless servo motor for load control of the feed grinding head, automatic compensation for grinding wheel loss and automatic reset prompt for replacement after loss to reduce the skill requirements of operators and achieve unmanned monitoring on line.

KEDA's new high-speed automatic production transfer packaging machine covers the full range of conventional ceramic tile specifications and the packaging speed exceeds 12 packages/min. Highly integrated key functional components result in a compact and flexible layout and specification conversion with one click achieves a simple and convenient operation/production changeover.

The stacking laser AGV and intelligent warehousing solutions that meet various needs of domestic and foreign customers presented by KEDA Intelligent Warehousing Business Division had received high recognition from customers.

★ Leading the industry forward to lower-carbon and more intelligent production with sustainable innovation ★

To coincide with the theme of "lower carbon and smarter" at 2023 Uniceramics Technology Expo, in addition to the whole line technology and machinery for the industries of ceramic tiles, sanitary ware, foamed ceramics, and lithium carbonate etc., KEDA Electromechanical had showed more powerful and smart V3.0 intelligent control system for kilns. The system has many functions such as "real-time, dynamic and customized production data query" and "dynamic simulation of tiles moving in kiln", "automatic adjustment system for kilns and empty kilns" and "formula management", providing better and smart solutions for the intelligent manufacturing of enterprises.

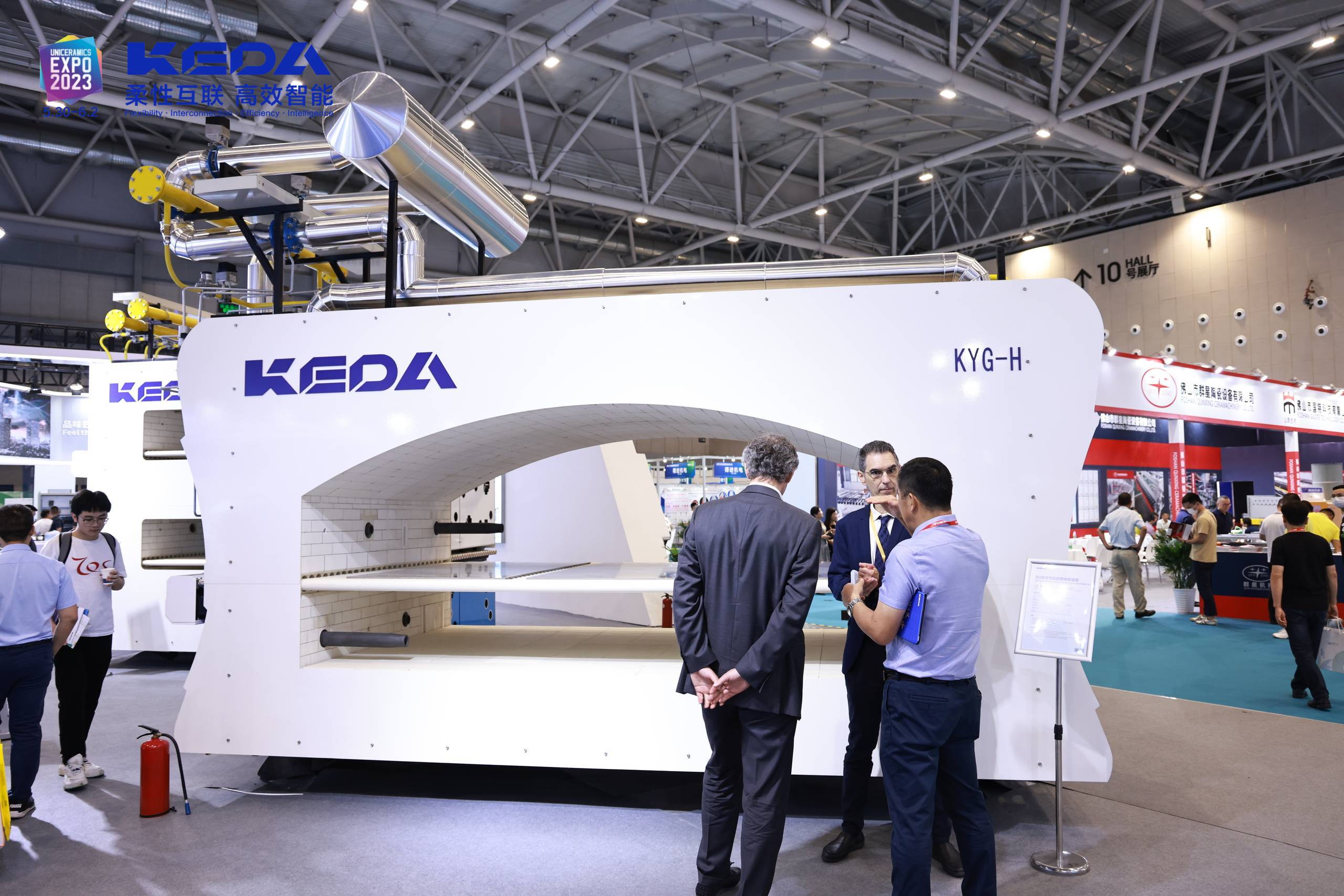

To assist in the green and sustainable development of the global ceramic industry, KEDA Electromechanical also showcased an New kiln has applied the advanced hydrogen energy mixed combustion technology. Without changing the original structure, it can realize multiple combustion combinations with a hydrogen mixing ratio of 10%, 20%, and 30%, resulting in higher combustion efficiency, more stable flames and better furnace temperature uniformity. Double flowmeters are used to control the hydrogen mixing ratio accurately to ensure its stability. The launch of KEDA‘s efficient and energy-saving ultra wide-bodied roller kiln powered with hydrogen opens a new technical path for the green and low-carbon development of the ceramic industry.

★ KEDA Zhentao MOM New Product Launch ★

KEDA hosted a meaningful event in Hall 10 on the first afternoon of the exhibition, named "Digital Empowerment and Future Intelligent Manufacturing" - experience sharing of digital transformation of ceramics machinery and equipment industry cluster and new product release of KEDA Digital MOM. The event specially invited Jinsong XIAO, director of the Institute of Materials Industry of China Center for Information Industry Development (CCID) of the Ministry of Industry and Information Technology (MIIT), to share topics about how to develop the manufacturing industry with high quality in the context of dual-carbon.

A signing ceremony for "Foshan Ceramics Machinery and Equipment Industry Cluster" was held at the event and six brand enterprises in Foshan, including Newpearl Group, Hongyu, Xinruncheng Ceramics, Fangxiang Ceramics, Oceano and New Jincheng Ceramics, signed agreement to join the cluster. Foshan Ceramics Machinery and Equipment Industry Cluster is jointly promoted by KEDA Industrial Group, Meicloud and China Mobile. It aims to find native digital solutions for ceramic industry, remove barriers against the development of ceramic industry and help enterprises increase profitability and efficiency.

KEDA Digital MOM, a manufacturing and operation management system for ceramics factories, was officially launched before guests of industry. Developed by the KEDA Ceramic Digital Factory Business Division, the system is committed to providing professional, implementable and highly reliable digital manufacturing solutions for the ceramic industry. It makes ceramic production more intelligent and management more smart by integrating the management process, production, equipment, quality, energy, cost, and other businesses of the ceramic industry. The new system brings the transformation of business management for the industry to promote the development of information and intelligence and achieve digital transformation and upgrading of enterprises.

The event has showed the way for the digital transformation and upgrading of the industry. Through the collaborative empowerment of the ceramics machinery and equipment industry cluster, it will certainly make the production and operation of ceramic enterprises more efficient and more competitive, and promote the high-quality development of the ceramic industry.

On the first day of the exhibition, two small new product promotion meetings were held at KEDA as well to enable customers more clearly understand the innovation and progress of KEDA products with a closer look. In the coming days, we will have more activities with more wonderful products. Welcome to KEDA booth and there are more surprises awaiting you.

(Kang AN, KEDA Ceramic Machinery)

loading...

loading... 01 Jun 2023

01 Jun 2023