Here comes the questions. Why was the high-hydrogen wide-body kiln first established in the Henan production area? What challenges did the technical development face? What is the significance of hydrogen-powered kilns?

To answer these questions, Mr. Ceramic has specially invited DLT Technical Director, Mr. Xiru CHENG, to shed light on the ins and outs of DLT's research and application of hydrogen energy.

| Overcoming Challenges

For Hydrogen's Fast Combustion and Short Flame, How to Adapt to High-Output Wide-Body Kilns

As environmental requirements intensify, ceramic enterprises increasingly demand clean energy. Hydrogen energy, with its high calorific value, non-toxicity, and zero carbon emissions, has been a focus of DLT's efforts in energy conservation and carbon reduction. The company began its R&D of hydrogen technology many years ago. During the COVID-19 pandemic, travel restrictions inadvertently provided DLT's researchers with ample time to overcome key technical challenges related to high-hydrogen wide-body kilns.

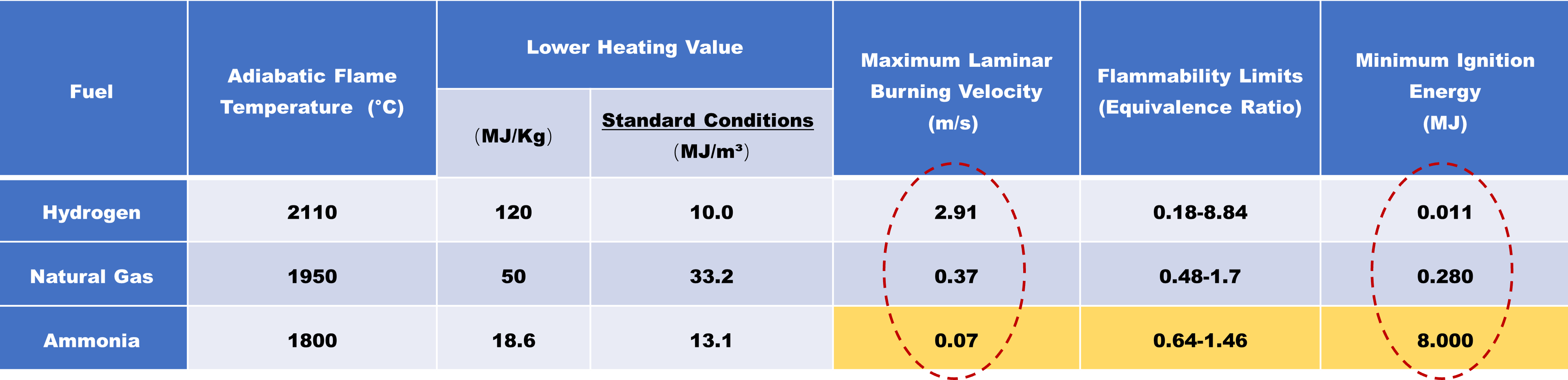

Mr. Xiru CHENG pointed out three main technical challenges faced by high-hydrogen wide-body kilns:

- First, in actual production, hydrogen burns quickly and has a short flame. Meanwhile, the wide-body kiln with large output has significant cross-sectional temperature differences. Adapting these two factors requires addressing the issue of high-speed injection through careful burner selection and design. Additionally, the short flame and concentrated high heat from hydrogen combustion can affect the lifespan of kiln materials, such as kiln walls and silicon carbide sleeves. Therefore, these factors must be fully considered in kiln design.

- Second, hydrogen is highly reactive, posing a backfire challenge. To address this, DLT introduced check valves and other components.

- Third, the material design and construction standards for hydrogen pipelines must strictly comply with the Chinese national standard GB 4962-2008 Technical safety regulation for gaseous hydrogen use.

As DLT overcame the key technical challenges of high-hydrogen wide-body kilns, a significant favorable development emerged: China announced clear timelines for achieving carbon peak and carbon neutrality. On September 22, 2020, at the General Debate of the 75th Session of the United Nations General Assembly, China announced its aim to reach peak carbon emissions by 2030 and achieve carbon neutrality by 2060.

This serious commitment to the carbon peak and carbon neutrality strategy has drawn significant attention both in China and the international community. It also provided authoritative Chinese national endorsement and momentum for high-tech enterprises like DLT, which are dedicated to energy saving and carbon reduction.

| Implementation

Outstanding results in cost reduction and efficiency improvement, Significant energy-saving and carbon-reduction effects

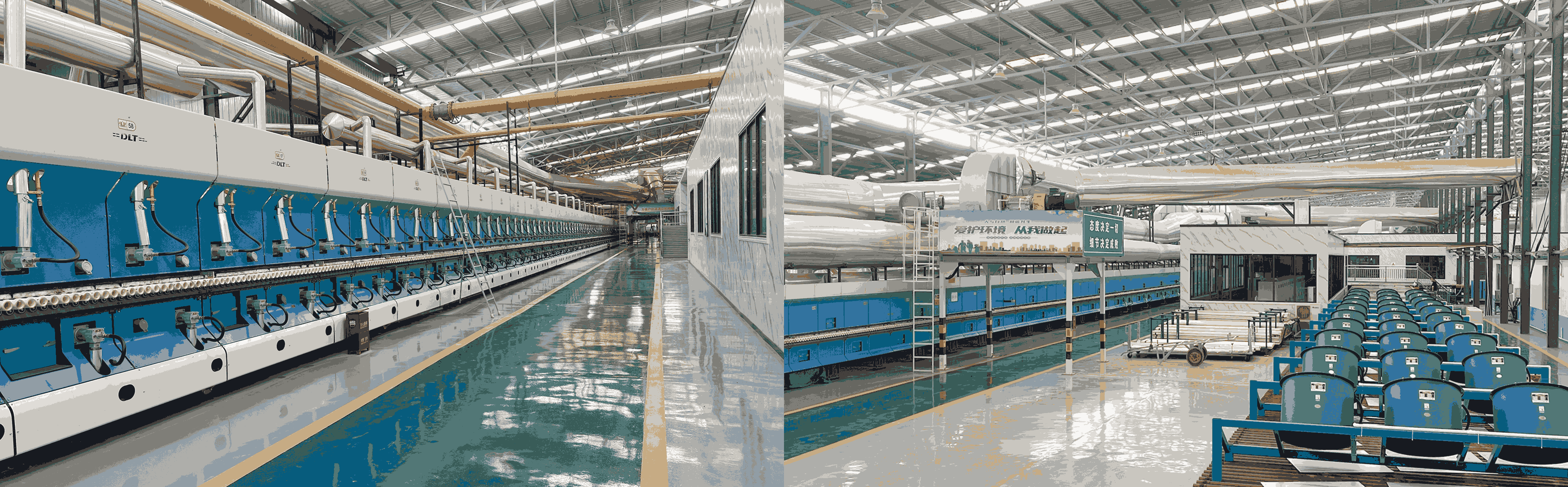

Just six months after the project initiation, on February 18, 2022, the intelligent production line of sintered stones/large slabs for Henan Zhongqi Ceramics, constructed by HLT&DLT, was launched. This line features a wide-body kiln with an internal width of 3.1 m, a daily production capacity of 38,000 ㎡, and a fuel hydrogen content of 60%. It has opened a new chapter for high-hydrogen wide-body kilns in the ceramics industry.

To date, due to its energy advantages, this high-hydrogen wide-body kiln has shown significant characteristics in cost reduction, efficiency improvement, and energy saving and carbon reduction. According to Mr. Xiru CHENG, the fuel costs of this production line are about 30% lower than using natural gas locally. Customers report that the kiln not only has evident energy-saving advantages but also produces high-quality products.

The carbon reduction effects are also highly significant. At current production levels, using high-hydrogen mixed gas results in approximately 30,200 tons of CO2 emissions annually. If natural gas were used instead, the emissions would be about 41,000 tons per year. In contrast, the high-hydrogen wide-body kiln reduces CO2 emissions by approximately 26%.

Additionally, the production line is equipped with HLT&DLT's advanced DDI4.0-A intelligent central control system. The system utilizes cloud computing and comprehensive management to overcome spatial and temporal limitations, enabling remote monitoring of the production line.

| Refinement

Ammonia-Hydrogen Combustion Technology Soon to Be Mass-Produced, Laying the Foundation for the "Zero Carbon Era"

HLT&DLT, grounded in innovation, is not content with the breakthroughs achieved with high-hydrogen wide-body kilns. The technological development route and industrial practice from carbon reduction to low carbon and then to zero carbon represent DLT's clear plan to achieve the carbon peak and carbon neutrality goals.

On December 27, 2021, DLT, together with Foshan Xianhu Laboratory and OCEANO Ceramics, established the "Advanced Zero Carbon Combustion Technology Joint Innovation R&D Center". On December 18, 2022, they produced the world's first "zero-carbon ceramic tile" using ammonia-hydrogen fuel. This marked a significant milestone.

On October 28, 2023, DLT, Foshan Xianhu Laboratory, Oushenno, Monalisa, and Anqing Technology launched the "Ceramic Slab and Tile Mass Production Line Advanced Ammonia-Hydrogen Zero Carbon Combustion Technology Demonstration Project". They plan to launch the production line in the second half of 2024.

Mr. Xiru CHENG stated that for the mass production line of "ammonia-hydrogen zero carbon combustion technology", all 5 companies are leveraging their strengths. With no reference cases to follow, they had to build the technical procedures for ammonia-hydrogen fuel transport, storage, and combustion from scratch. Happily, this challenging process has been successfully overcome.

The upcoming mass production of the "ammonia-hydrogen zero carbon combustion technology demonstration project" represents a forward-looking layout by the five companies such as DLT focusing on the future. This marks a significant leap from theory to practice. It will lay a solid foundation for the ceramics industry to advance towards the "zero carbon era".

It also opens a new path for the low-carbon transformation of the high-temperature manufacturing industries through the application of the "new quality productive forces". This project contributes important technological support to the carbon peak and carbon neutrality strategy.

(HLT&DLT)

loading...

loading... 08 Aug 2024

08 Aug 2024