As a leading global enterprise in the building ceramic machinery industry, KEDA Industrial Group is the only company in China capable of providing complete plant engineering & production machinery and services for building ceramics. The group owns four renowned brands: "KEDA", "HLT&DLT", "ICF & Welko", and "QUANITECH", ranking first in Asia and second in the world in terms of comprehensive strength. As of now, KEDA Industrial Group's ceramic machinery products have been sold to over 60 countries and regions, continuously expanding their global presence.

"Stride Leap" and "Competitiveness Enhancement" Become KEDA Industrial Group's Ceramic Machinery Business Keywords for 2023

Mr. Xuexian YANG, General Manager of KEDA Industrial Group (600499. SH) summarized the leading Chinese ceramic machinery company's 2023 with three phrases: "stride leap", "competitiveness enhancement", and "satisfaction yet dissatisfaction".

The "stride leap" refers to the significant qualitative progress made compared to previous years, attributed to the "enhancement of core competitiveness" over the past year. The areas of "satisfaction yet dissatisfaction" are mainly related to the performance affected by adverse macroeconomic factors last year.

Due to the Chinese real estate slump and the global economic slowdown, KEDA Industrial Group's ceramic machinery business experienced an overall decline in 2023. According to the financial report, KEDA Industrial Group's 2023 operating revenue, net profit attributable to shareholders of the listed company, and net profit attributable to shareholders of the listed company excl. non-recurring profit or loss were RMB 9.696 billion, RMB 2.092 billion, and RMB 1.879 billion, respectively. The building materials machinery business achieved revenue of RMB 4.477 billion, a year-on-year decrease of about 20%; however, the gross profit margin increased by 2.38 percentage points to 28.39%. Notably, the international order ratio for the core ceramic machinery business exceeded 55%.

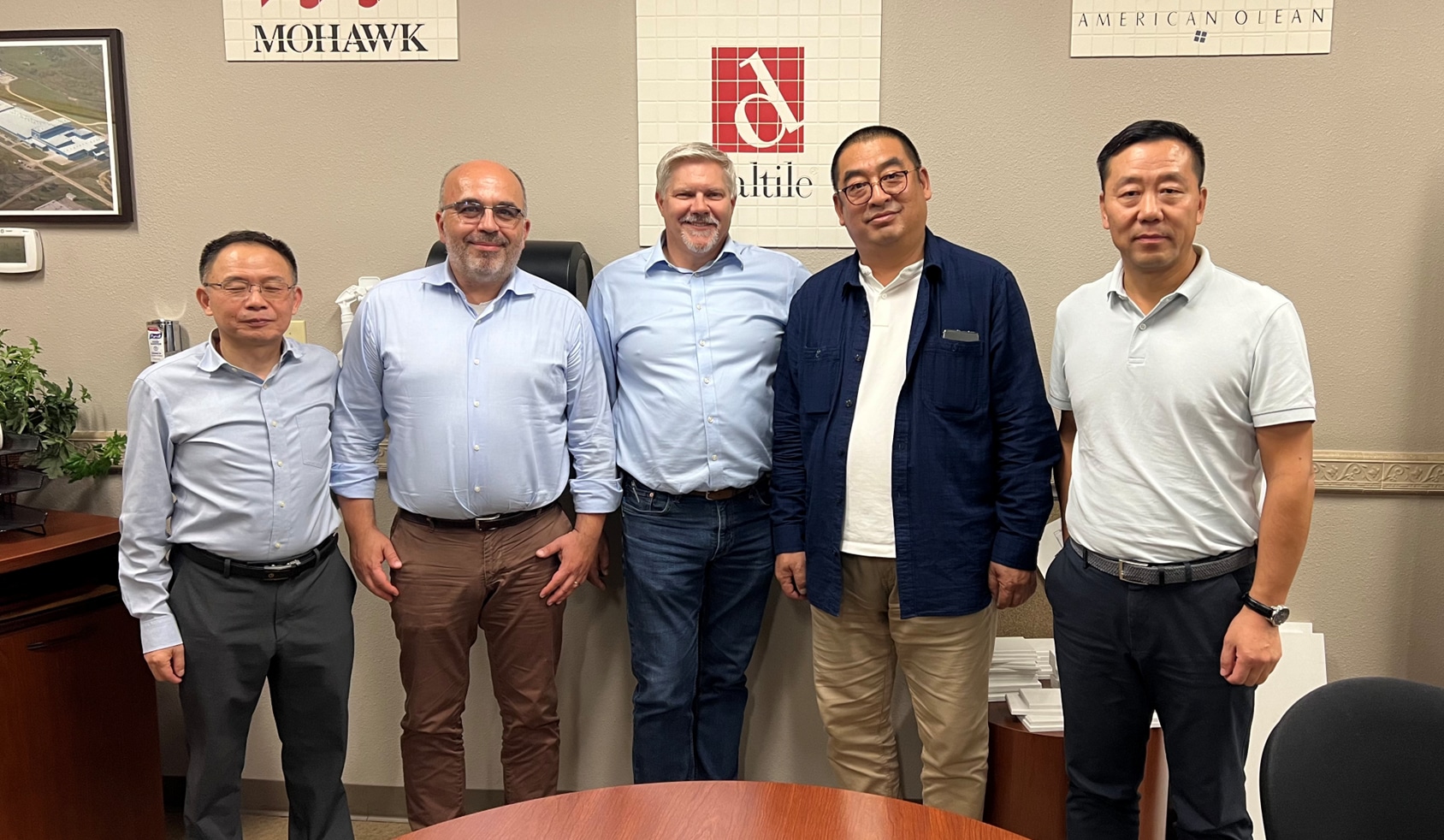

The company has strategically expanded its global market presence, with an increasing proportion of revenue and orders coming from international markets. In the latter half of last year, after Mr. Xuexian YANG toured major global ceramic production regions, he observed that despite the unfavorable macroeconomic conditions, KEDA Industrial Group remained relatively ahead of its peers. The company has maintained strategic stability in the face of rapidly changing external environments by focusing on global expansion and technological leadership.

KEDA Industrial Group has developed a nearly million-square-meter collaborative production layout between Chinese and international facilities by establishing production bases and acquiring land globally. Additionally, the company has also established subsidiaries in Indonesia and other international offices, set up parts & consumables warehouses, and extended its industrial chain by acquiring the Italian mould company F.D.S. Ettmar and taking stakes in SinoCera Create-Tide, a leading ceramic pigment & glaze and ink enterprise in China.

These efforts have strengthened KEDA's global marketing network, management team, and supply chain integration, further deepening its global localization service system. As a leading representative of the Chinese ceramic machinery industry, KEDA Industrial Group made significant strides in its globalization strategy last year.

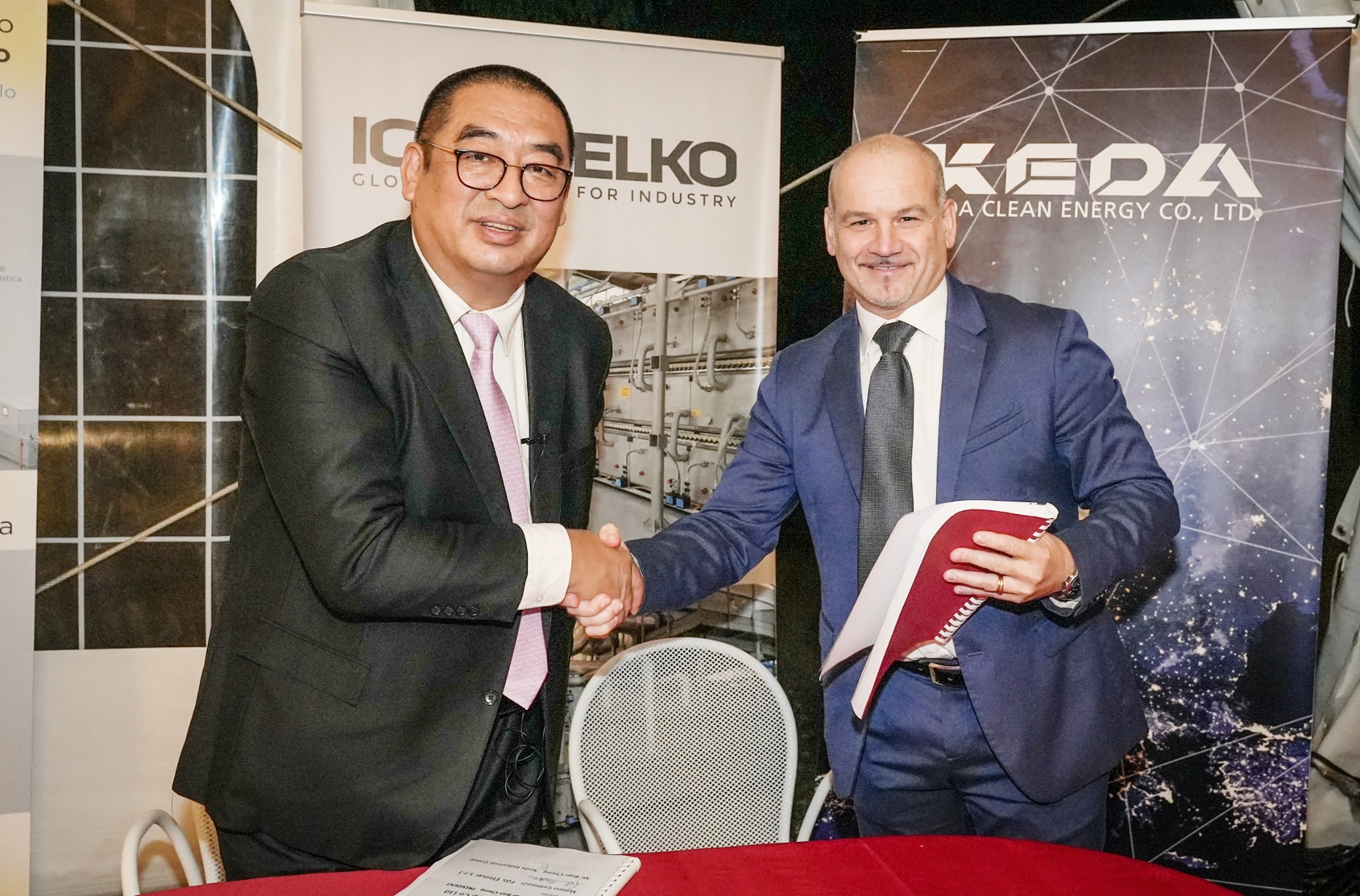

▲On September 25, 2023, Mr. Cheng BIAN, Chairman of KEDA Industrial Group, formally signed an agreement with Matteo Gelmuzzi, General Manager of the Italian mould manufacturing company FDS, thereby acquiring a 70% stake in FDS.

"Today, it's possible that not every company in the global building ceramics industry has purchased our products, but they certainly know KEDA Industrial Group," he remarked. "This level of recognition is rare among Chinese enterprises. There are over 100 countries with ceramic factories, and where there are ceramic factories, KEDA Industrial Group is known." Mr. Xuexian YANG expressed satisfaction with KEDA Industrial Group's globalization achievements and competitiveness in the ceramic machinery sector.

KEDA Industrial Group, along with SACMI, stands as one of the two leading companies in the global ceramic machinery industry—one with deep roots in Italy's longstanding ceramics heritage, and the other from China, dedicated to advancing industrial technology. From a competitiveness perspective, KEDA Industrial Group is rapidly catching up to its rivals. The evolution from "Made in China" to "Intelligent Manufacturing in China" is a crucial factor in KEDA Industrial Group's ascent to the top of the global ceramic machinery industry.

The introduction of relevant policies represents a significant boon for the ceramic machinery industry. In the face of new opportunities arising from a wave of machinery upgrades, products must align with trends in digitalization, energy conservation, and emissions reduction. KEDA Industrial Group has long been committed to digitalization, greenization, and servitization. As global market demands for ceramic machinery products evolve, KEDA Industrial Group is able to promptly offer the latest solutions that meet customer needs, thereby empowering the industry to foster new quality productive forces.

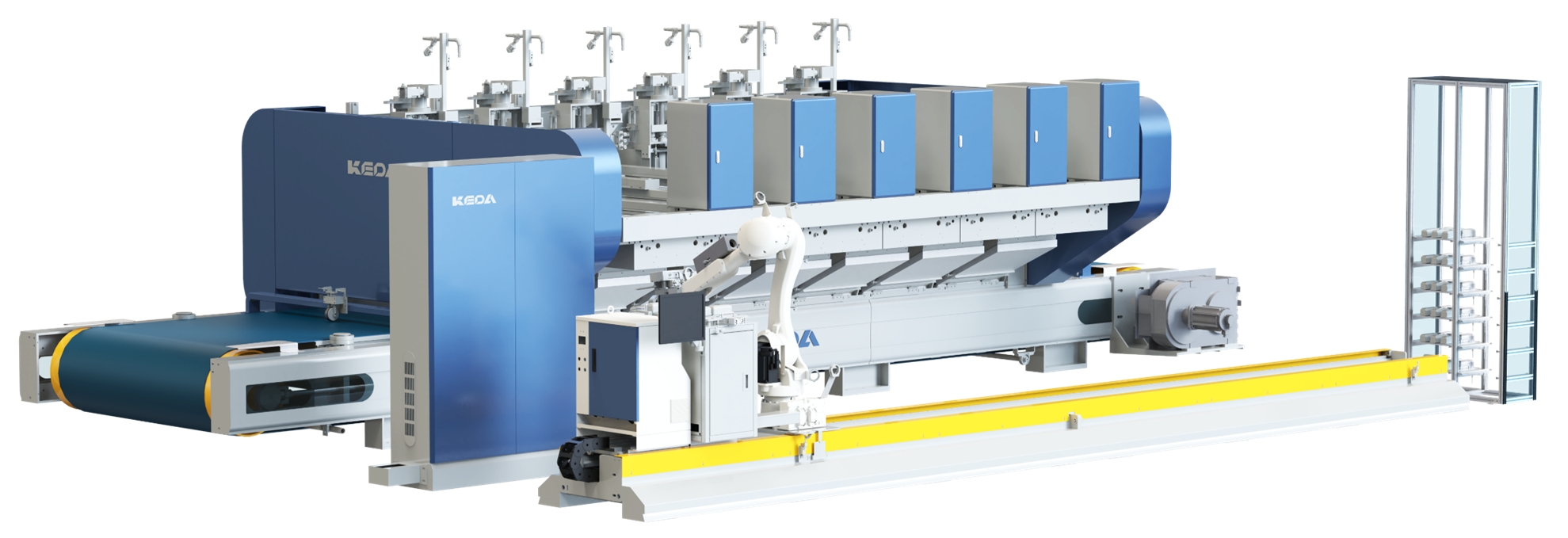

At the Foshan Uniceramics Expo 2024, KEDA Industrial Group showcased key ceramic processing machinery, such as the hydrogen-powered wide-body kiln and the multi-section swing intelligent polishing machine. These products embody the principles of high efficiency, intelligence, and green low-carbon technology, positioning KEDA at the forefront of the industry in terms of digital intelligence and energy conservation and emission reduction.

The multi-section swing intelligent polishing machine presented at the exhibition stands out by reducing the number of grinding heads by 30%, enhancing processing quality by 20%, and lowering single-machine energy consumption by 30%. It can also be integrated into a centralized control system for the entire production line, enabling remote operation. Furthermore, the replacement time for single-head grinding blocks is ≤90 seconds without requiring manual intervention, significantly reducing worker labor intensity while enhancing safety and automation.

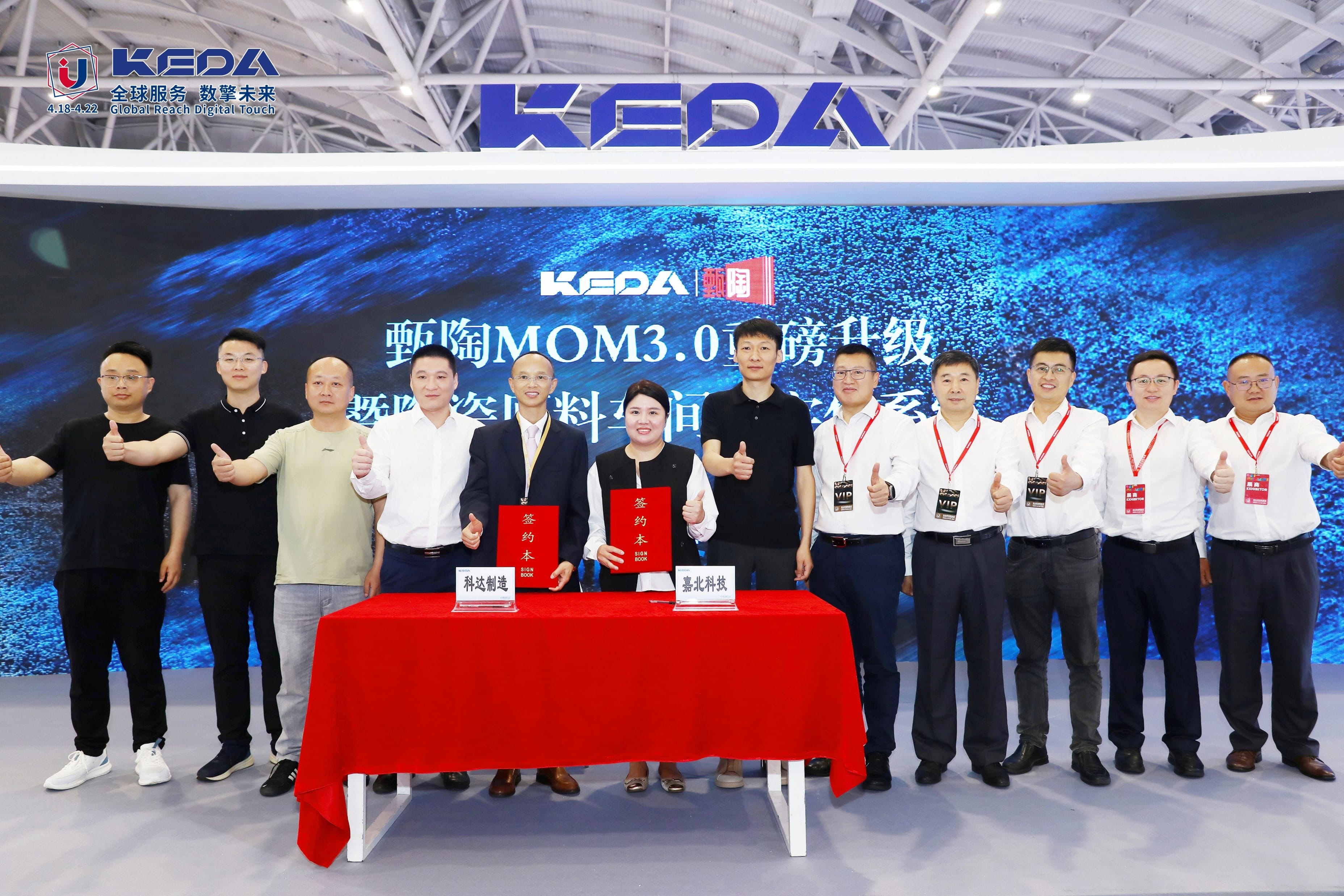

"Digitalization must enhance quality and efficiency for the company, yielding tangible results rather than digitalizing for the sake of digitalization," said Mr. Xuexian YANG. At the Foshan Uniceramics Expo 2024, KEDA Industrial Group also showcased its digital factory project, Zhentao MOM 3.0, and secured contracts for digital factory projects with several clients. Unlike typical digital factory projects, Zhentao MOM 3.0 integrates AI and incorporates intelligent process modules. By collaborating with leading industry models, it customizes optimal process optimization routes for ceramic enterprises.

Specifically, Zhentao MOM 3.0 has integrated digitalization and intellectualization throughout the ceramic complete plant, enabling transformative management in energy management, machinery management, cost accounting, and quality management. This promotes energy conservation, emission reduction, and quality and efficiency improvements, thereby enhancing the competitiveness of ceramic enterprises in an environment of declining demand, intensified competition, and severe internal pressure.

Over the years, KEDA Industrial Group has continued to innovate and surpass itself. Leveraging a robust R&D system and sustained R&D investment, it has accumulated numerous innovative research and development achievements.

Over ten projects such as "Key Technology Development and Industrialization of AI Vision-based Intelligent Detection Line for Grading and Color Sorting of Building Ceramic Wall and Floor Tiles", "Key Technology Development and Industrialization of Intelligent Polishing Line for Building Ceramics", and subsidiaries like DLT's "High-Efficiency and High-Output Cellular Ceramic Tunnel Kiln Complete Set of Machinery" and "Zero-Carbon Firing Ceramic Tile Pilot Production Application Demonstration" passed technological achievement evaluations in 2023.

"New quality productive forces" offer a solution template for traditional manufacturing—automation, intelligence, and digitalization. KEDA Industrial Group extends this template into its core competitiveness—"product + service." Mr. Xuexian YANG stated, "Previously, we only sold products. Now, we also sell services, which are technically enhanced services."

According to him, KEDA Industrial Group offers comprehensive support and services. "When customers need spare parts or consumables, KEDA Industrial Group can ship them from the nearest global service point or parts warehouse and deliver them quickly."

As a typical discrete heavy machinery manufacturing enterprise, KEDA Industrial Group's ceramic machinery products have many parts, are complex, have long production cycles, and are difficult to control during the production process. In the context of developing new quality productive forces, KEDA Industrial Group has been promoting digital factory and digital workshop construction internally, introducing digital design tools to continuously improve production efficiency and product quality.

"We extend technological transformation from hardware to software. From 2021 to 2023, we invested heavily in hardware, focusing on upgrading to more automated, precise, and digital machinery. In terms of software, the main investment was in digital processing, which has brought us some dividends," says Mr. Xuexian YANG. Over the past few years, KEDA Industrial Group has seen significant operating revenue growth while maintaining stable personnel numbers, indicating a substantial increase in personnel efficiency.

"Comparing the performance of the Polishing Division in January 2024 with January 2022, achieving a monthly output value of over RMB 100 million previously required at least 200 workers, but now it only requires about 120 people. In the past, the delivery cycle for a ceramic polishing & squaring production line was approximately 45 days. However, after digital transformation, the delivery cycle has been reduced to 25 days. Digital construction has unleashed greater productivity at KEDA Industrial Group, significantly improving delivery efficiency," explained Mr. Xudong SUI, Deputy General Manager of KEDA Ceramic Machinery and General Manager of KEDA Polishing Division.

Leveraging its core research and development capabilities along with excellent management, KEDA Industrial Group is equipped with an entire industry chain system, technological support, and a service network layout, securing numerous customer orders.

"In the first quarter of 2024, the company's ceramic machinery saw substantial growth in both orders and deliveries, with major growth coming from international markets, and the parts & consumables services also achieved good results. Regionally, the fastest order growth came from Europe. Traditionally, KEDA Industrial Group's ceramic machinery products have been favored by developing and emerging countries, while markets in Europe and North America have long been dominated by Italian machinery. In recent years, through measures such as intelligent transformation, our ceramic machinery products have reached levels of automation and intelligence comparable to Italian products, while we maintain advantages in high output and low costs." KEDA Industrial Group mentioned in an official announcement the impact of the intelligent transformation of its ceramic machinery products on order quantities.

"Since the company's acquisition of the Italian ceramic machinery company ICF & Welko in 2018, we have aimed to integrate Italian manufacturing to enhance our product line and capabilities. For instance, we manufacture the mechanical components in China, leveraging the comprehensive supply chain and lower material costs. Meanwhile, for electrical control and automation, we utilize ICF & Welko in Italy, ensuring the products align with the usage habits of our European and American customers. The results have been evident, with a steady influx of orders from Europe," stated KEDA Industrial Group.

Meeting customer needs is the primary criterion for a company's survival, followed by creating additional value. The products transformed through intellectualization and greenization, along with a responsive service network, are establishing KEDA Industrial Group's competitive edge in the industry.

The Global Building Ceramic Machinery Market has a Bright Future, with Long-term Strategic Stability Transcending Business Cycles

Predicting the development of the building ceramic machinery industry is closely linked to the trends in the real estate market. Over the past few decades, the rapid growth of China's real estate sector has significantly bolstered the ceramic machinery industry. However, for continued growth, the Chinese ceramic machinery industry must focus on the global market.

"Building ceramic manufacturing is a vast industry, and I have always been optimistic and confident about it from a global market perspective," said Mr. Xuexian YANG. He believes that KEDA Industrial Group's global strategy, implemented over a decade ago, meets substantial demand across Africa, India, and Europe and America. The global market remains promising.

Nevertheless, business development is never without challenges, and the industry follows its own development patterns. Facing a rapidly changing external environment, KEDA Industrial Group must adapt proactively. The company has long agreed that the positioning of its ceramic machinery business must shift from a machinery supplier to a production service provider, ensuring smooth progression into the next business cycle.

To date, KEDA Industrial Group has established a vast service network globally. On one hand, it benefits from the scale advantages of KEDA Ceramic Machinery and HLT&DLT, as well as the huge capacity support of building materials, with clear advantages and quality assurance in centralized procurement of spare parts, consumables, raw materials, ink, rollers, etc.

On the other hand, after acquiring the Italian mould company F.D.S. Ettmar, KEDA Industrial Group has improved the structure of global service personnel, including international mould service personnel, and formed an experienced global service team, which can definitely provide global customers with a "three-savings" model namely after "convenient, worry-free, and cost-effective" , as highlighted by Mr. Cheng BIAN, Chairman of KEDA Industrial Group.

"Keeping pace with the times" is a strength of KEDA Industrial Group. Mr. Xuexian YANG emphasized that whether the company is upgrading its transformation or creating new productivity, staying abreast of the times is crucial. Enhancing manufacturing capabilities, research and development capabilities, and delivery capabilities in accordance with the changes of the era is essential for sustaining profitability.

Today, KEDA Industrial Group has accumulated extensive experience in facing global markets and will continue advancing along the strategic axes of globalization, servitization, and digitalization, aiming to solidify its position within the industry's top 1%.

"No matter how future concepts evolve, maintaining competitiveness and staying current are the long-term paths to success. Continuously driving enterprise transformation and product upgrades is crucial," Affirmed Mr. Xuexian YANG regarding KEDA Industrial Group's competitiveness. He firmly believes that "through diligent work and dedication to product excellence, great enterprises can shape the era."

(KEDA Ceramic Machinery)

loading...

loading... 06 Aug 2024

06 Aug 2024