The Indian ceramic industry, having undergone significant growth and reorganization, is now entering a new development phase. To address challenges such as increased natural gas prices, rising labor costs, and the demand for upgraded products, Indian ceramic companies are enhancing industrial efficiency. They are also emphasizing energy savings, reduced consumption, and increased automation and smartness in their production line equipment.

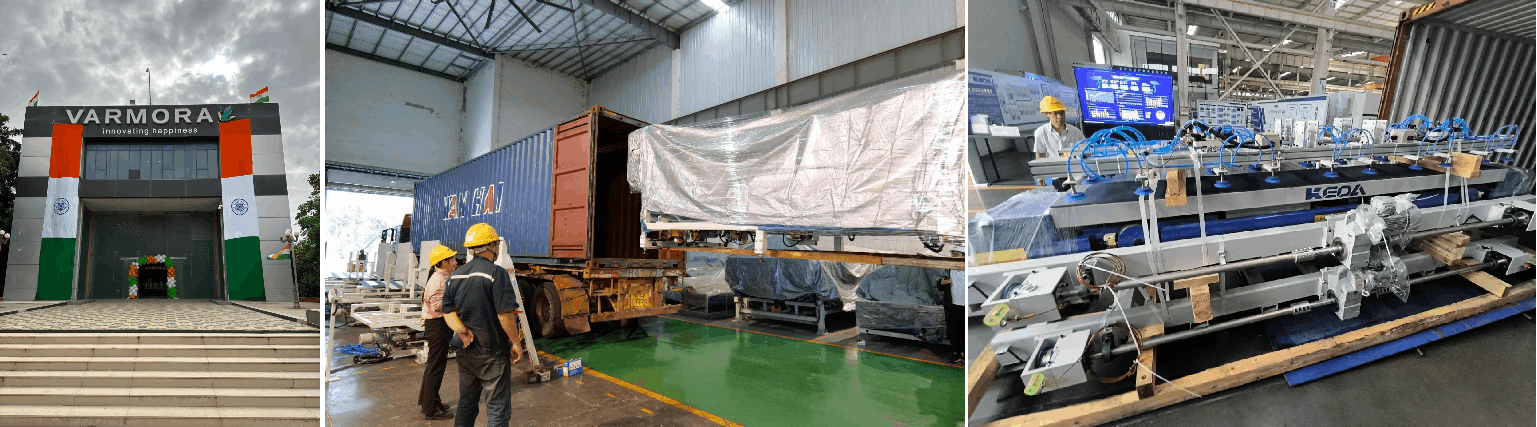

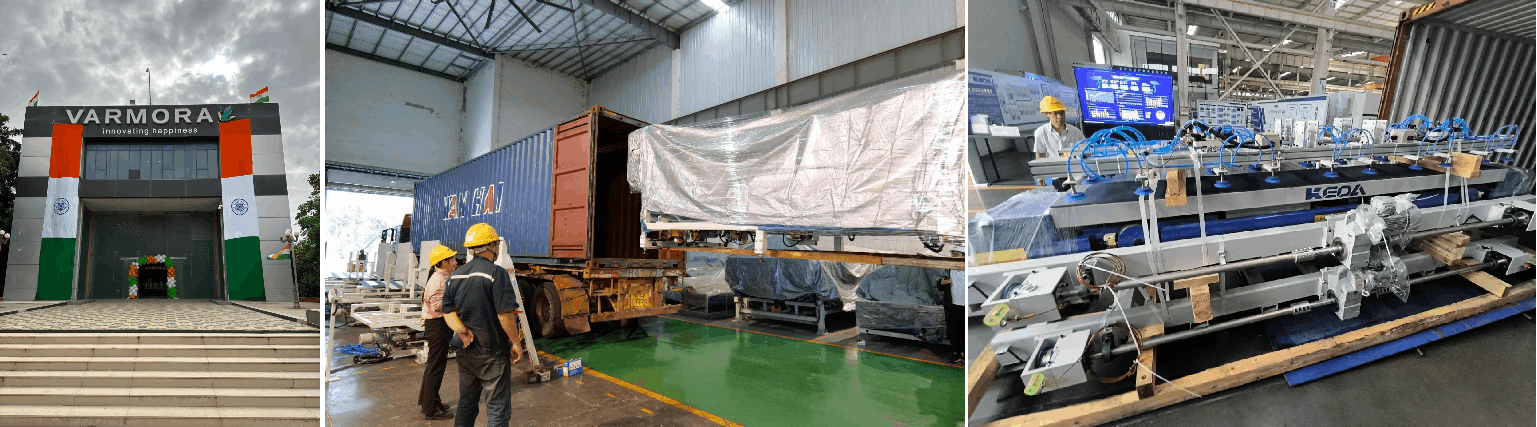

Recently, KEDA has successfully shipped batches of a customized post-kiln complete line to Varmora Granito Pvt. Ltd. (hereinafter referred to as Varmora), a prominent ceramic company in India. This marks the introduction of the first fully connected-model smart post-kiln complete line in the Indian market. KEDA's collaboration with Varmora is aimed at advancing Indian ceramic production towards greater flexibility, efficiency, and smartness.

Established in 1994, Varmora is a prominent manufacturer of ceramics and bathroom products in India. With over 5,000 retail stores and 700 dealers across the country, it also boasts approximately 20 branches and employs over 1,200 professionals. Varmora is dedicated to delivering innovative and sustainable products and solutions to its customers. Their product offerings reach 74 countries and regions worldwide.

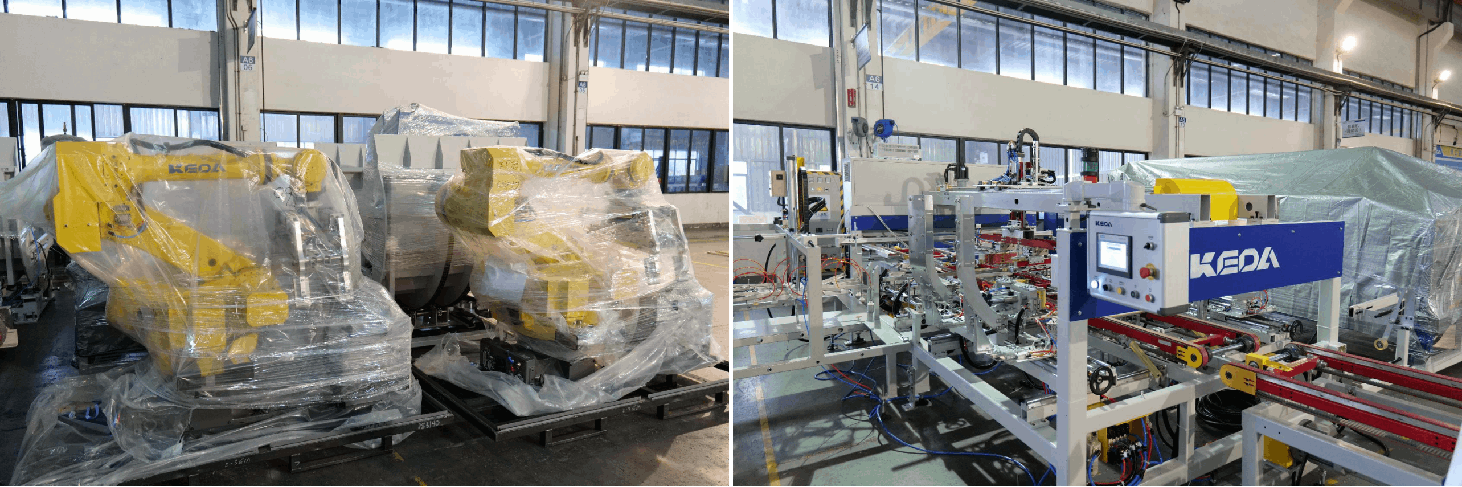

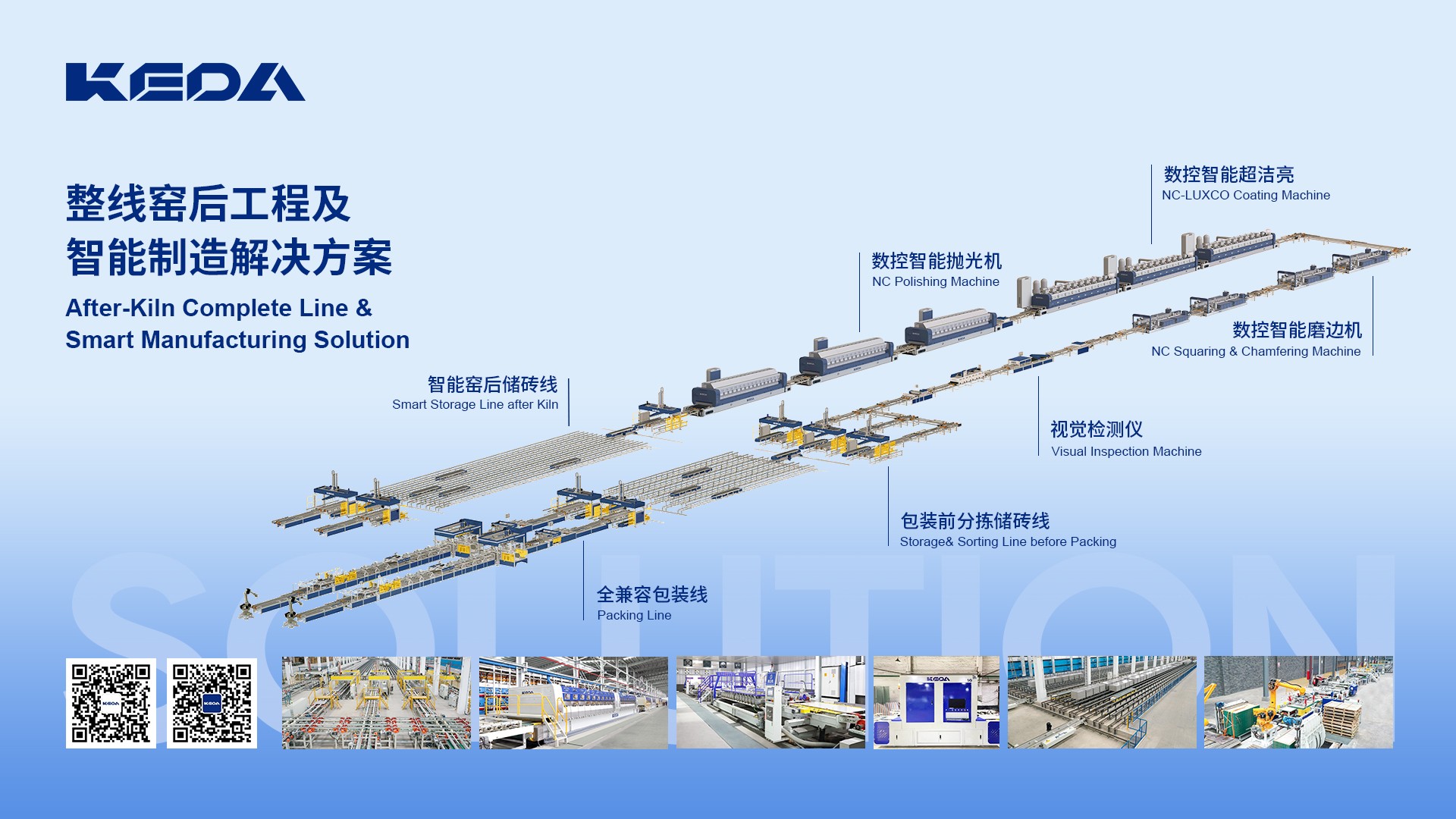

In an effort to meet Varmora's requirements for producing high-quality glaze polishing and antique products, KEDA has tailored a post-kiln complete line. This custom solution includes KEDA's smart tile post-kiln storage line, high-efficiency smart polishing complete line, pre-packaging smart tile storage line, and large-size rapid-packaging complete line. Additionally, for Varmora's super-large-size slate line of 1600×3200mm, KEDA customized a numerical control smart large-slab polishing line. KEDA's innovative solutions have enhanced Varmora's production line and strengthened its competitiveness in the market.

The first application of the KEDA smart storage and transportation system in India is a major breakthrough for this project. This system enables automatic tile storage allocation, and tasks such as loading tiles, unloading tiles, and warehouse management are automatically assigned by the system, eliminating the need for manual selection of tracks, which significantly reduces labor and operational frequency. Furthermore, it incorporates inventory management, generating reports on inventory levels, product types, kiln exit times, and loss statistics, among other production-related information. With full-link digital management, it offers real-time task adjustments, optimal vehicle allocation, path planning, and resource distribution, ensuring adaptability to the actual production environment and resulting in a more flexible and smart production process.

As labor costs continue to rise in India, the successful implementation of the KEDA smart post-kiln complete line at Varmora sets a new example in the country. This achievement will assist customers in reducing labor, enhancing production efficiency, saving energy, improving product quality, and cutting overall costs. It will accelerate the adoption of post-kiln complete lines in the Indian ceramic industry and support the transformation and upgrade of Indian ceramic manufacturing towards greater automation, smartness, and digitalization.

With a 23-year presence in India, KEDA has grown alongside the Indian ceramics industry, playing a significant role in its development and transformation. Through ongoing product innovation and localization efforts, KEDA has made a deep impact on the Indian ceramics sector. From India's first KD16008 ultra-large tonnage press to India's first 3.85-meter internal width all-glazed-tile wide-body kiln, and now the introduction of the first smart post-kiln complete line, KEDA has been driving technological advancement and upgrading in the Indian ceramic industry through innovative solutions. KEDA's subsidiaries in India also deliver top-quality components, consumables, and maintenance and refurbishing services for polishing lines. Meanwhile, KAMI in India provides high-quality ceramic inks and glaze products, enhancing the value proposition for Indian ceramic businesses.

Innovation leads the market, and service shapes the future. KEDA is committed to transforming the Varmora post-kiln complete line project into a beacon of the ceramic industry in India. As part of this new phase of development, we will collaborate with Indian ceramic companies, setting a new course for the Indian ceramic industry, driving multidimensional value and seeking a mutually beneficial future.

(KEDA Ceramic Machinery)

loading...

loading... 16 Nov 2023

16 Nov 2023