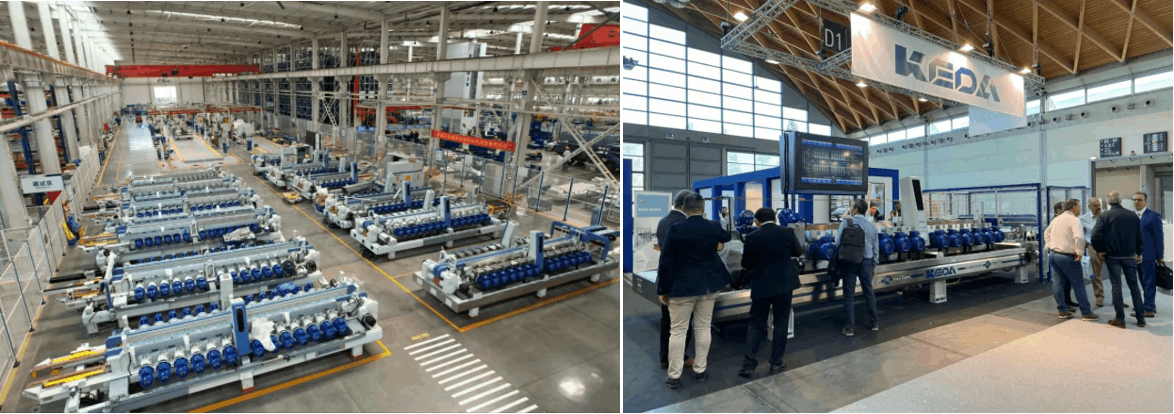

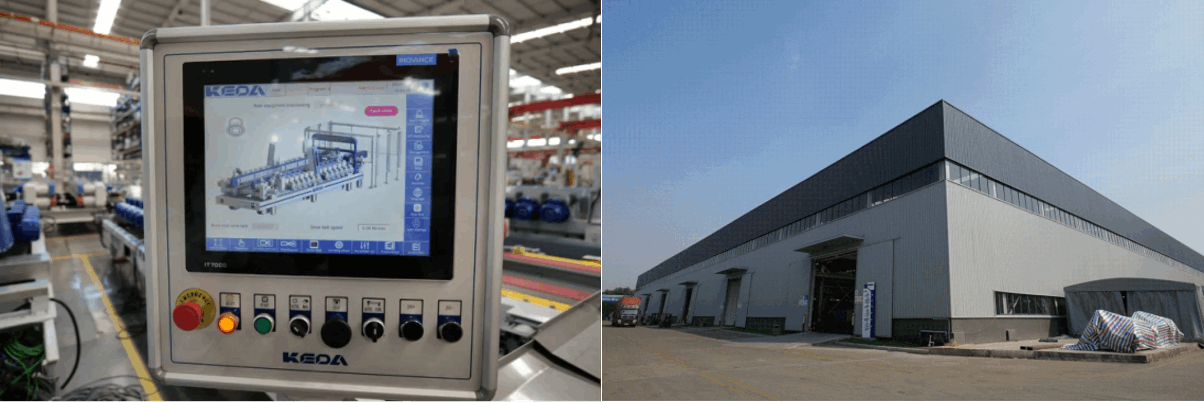

On October 10-11, KEDA Ceramic Machinery's customized 8 KEDA KING series efficient intelligent squaring & chamfering machines were successively shipped from KEDA's deep processing workshop to Italy. They will depart from Sanshan Port and arrive at the port of Genoa, Italy, in mid-November. In the near future, 3 KEDA KING series squaring & chamfering machines will be shipped to Algeria. This is the largest batch of shipments for KEDA KING series efficient squaring & chamfering machines within the year. KEDA's deep processing workshop has entered the busy end-of-year delivery season.

In 2022, KEDA's second-generation NC squaring & chamfering machine, developed in collaboration with Italy, made its first appearance at TECNA 2022, attracting widespread attention from customers in Europe and around the world.

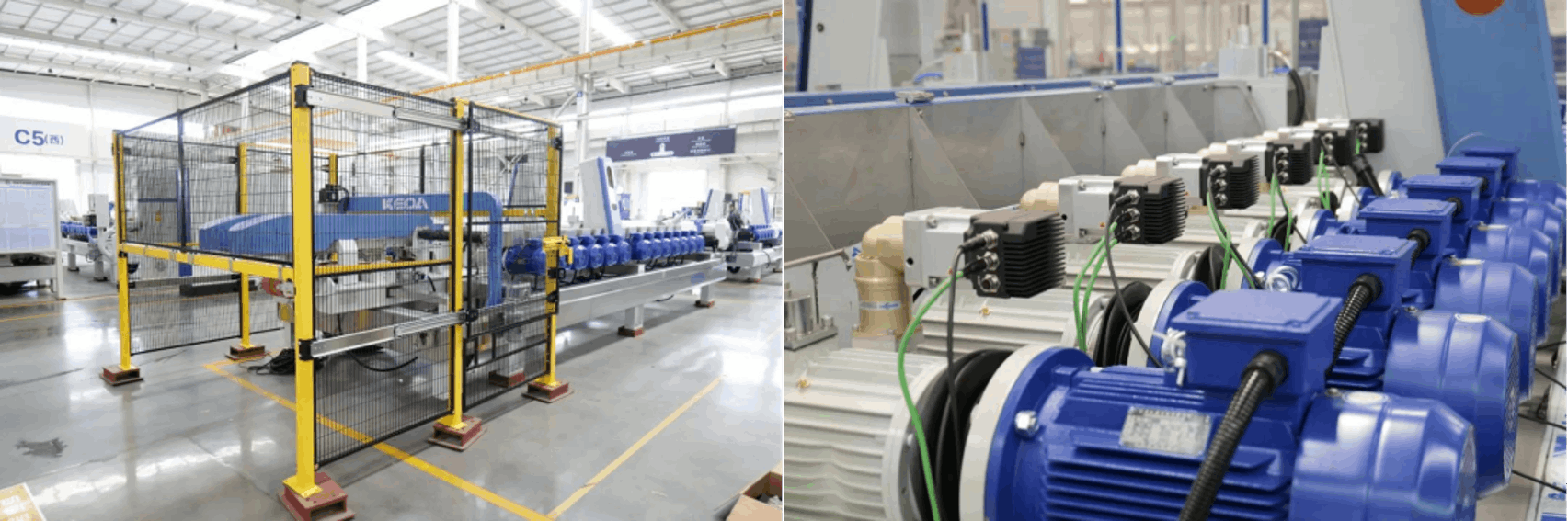

In 2023, building upon the second-generation NC squaring & chamfering machine, KEDA further optimized and upgraded to launch the KEDA KING series efficient intelligent squaring & chamfering machine. This machinery is newly developed and manufactured according to European standards, fully complying with CE safety requirements.

Technical Advantages of KING Series Efficient Intelligent Squaring & Chamfering Machines

- Higher Quality: Diagonal ≤0.3mm, tile edge straightness ≤0.13mm, achieving sealed laying.

- Better Compatibility: It adopts a new generation universal platform architecture, enabling compatibility between dry and wet squaring platforms. The working width ranges from 200mm to 3600mm, and the thickness ranges from 3mm to over 40mm

- Brand New Efficient Intelligent Servo Feed Squaring Head: This series achieves high-precision distribution of squaring amount, automatic compensation for squaring wheel consumption load, and is equipped with efficient motors to achieve rapid tile discharge. It is suitable for both dry and wet use, equipped with ф300 abrasive tools, and has a maximum speed of 5000r/min.

- Intelligent Brick-Pushing System: The high-speed brick-pushing system is complemented by safety protection devices and can be configured with an intelligent brick-pushing curve. The maximum brick-pushing speed is 130 pieces per minute, and the diagonal error is ≤0.3mm (taking 400X800 as an example).

- Brand New User Interface: The operation is simpler, with fixed experience parameters, tracking squaring & chamfering wheel lifespan, and lower maintenance costs.

- Laser Measurement System: It achieves 100% continuous detection of tile processing dimensions.

- Additional User-Friendly Design: The machine is equipped with an integrated squaring & chamfering wheel protective cover, facilitating quick removal and replacement of the squaring wheel. It also features a safety electromagnetic door lock and a squaring& chamfering wheel grinding observation window, making operation convenient.

Since the launch of KEDA first-generation NC squaring & chamfering machine in 2016, KEDA NC squaring & chamfering machine has gained favor among global customers due to its product characteristics of being "worry-free, easy to use, intelligent, and user-friendly". The machines have been exported to countries such as the United States, Brazil, Argentina, Turkey, and Italy, with a cumulative shipment of more than 600 units. This has brought tangible benefits to customers and greatly promoted the productivity enhancement of the ceramics industry.

From the development of NC squaring & chamfering machines to the upgrade to the KING series efficient intelligent squaring & chamfering machines, the introduction of multi-section smart swing polishing machines, and the centralized control system for architectural ceramic polishing lines, KEDA's deep processing has always been at the forefront of the era, continuously innovating and iterating, and leading the industry in technological advancement.

KEDA polishing & squaring machine shoulders the mission of pioneering entry into the European market. In 2021, KEDA successfully launched the first NC intelligent dry squaring line for 30-40mm thick tiles with double-zero water absorption in Italy. In 2023, KEDA exported a total of 8 machines from the KING series efficient intelligent squaring and chamfering lines, comprising 4 lines, to Italy. This demonstrates the recognition of KEDA polishing & squaring machine in the Italian market.

More than just polishing & squaring machine, in 2021, KEDA successfully launched a thick brick roller kiln production line for MASPE in Italy, becoming the first Chinese ceramics machinery brand to formally launch a roller kiln project in Europe.

In recent years, KEDA Industrial Group has been increasing its presence in the European market, starting from the acquisition of ICF & Welko to establishing a European subsidiary. Furthermore, this year, KEDA acquired a 70% stake in the Italian mold company FDS. By leveraging the collaborative innovation and sales channel sharing advantages of KEDA, ICF & Welko, and FDS, KEDA aims to strengthen its cooperation with customers and further expand its presence in the European market.

Innovation knows no bounds and the pursuit of excellence is eternal. KEDA will continue to intensify its innovation efforts, providing better products and services for ceramic users worldwide, driving progress in the ceramic industry, and working together to create a brighter future.

(KEDA Ceramic Machinery)

loading...

loading... 18 Oct 2023

18 Oct 2023