The 2023 Hunan (Liling) International Ceramic Industry Expo, coinciding with the Chinese Mid-Autumn Festival and China's National Day, attracted a lively crowd to the China Ceramic Valley International Convention and Exhibition Center. The exhibition covers an area of 30,000 square meters and consists of five exhibition halls. It has attracted over 400 exhibitors from 24 countries globally and 11 provinces (autonomous regions) in China to gather in Liling, showcasing its presence and grandeur. Following the principles of "grandeur, safety, innovation, and effectiveness", this ceramic expo emphasized three major themes: smart manufacturing, technological innovation, and openness and inclusivity. It also embodied professionalism, internationality, and interactivity.

Seizing this opportunity, DLT presented its high-end Intelligent EPC complete line for tableware production, along with cutting-edge technology and promotional materials. The DLT's presence at the exhibition, coupled with on-site professional interactions and attentive services, attracted numerous customers for discussions and garnered widespread attention. DLT celebrate friendship through ceramic and foster prosperity through technology

Since its establishment, DLT has devoted significant efforts to the research and development of high-end tableware and sanitary ware machinery. It has achieved significant achievement in integrating multiple technologies and automation with European machinery companies and has undertaken and completed numerous complete line projects in China and internationally. DLT has been at the forefront of international high-end tableware and sanitary ware kiln thermal machinery and complete production line engineering.

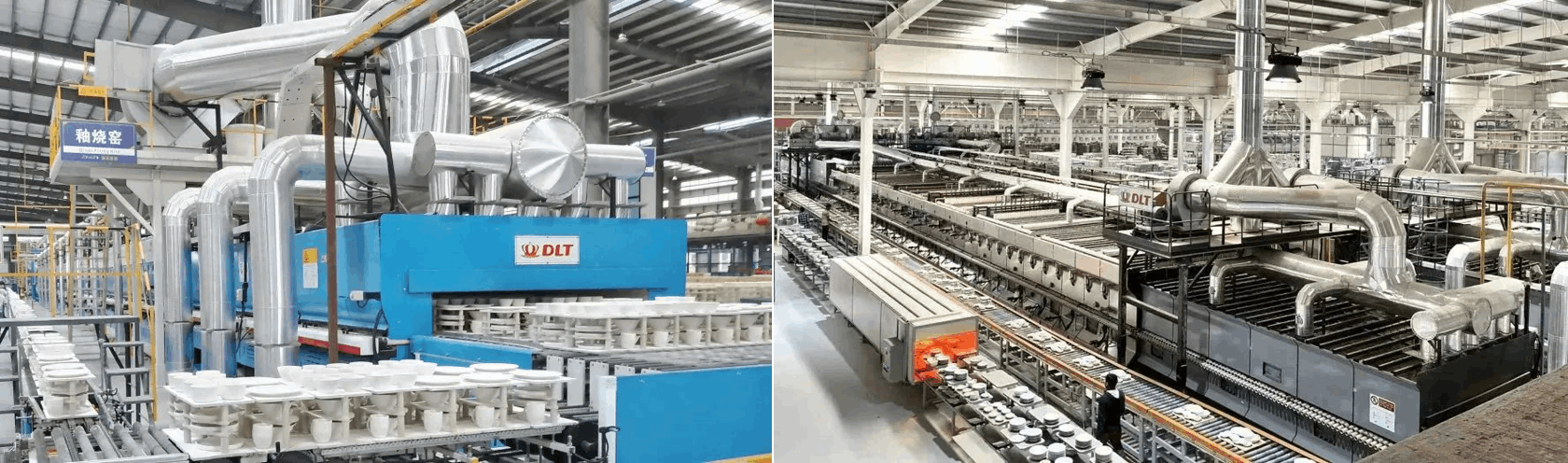

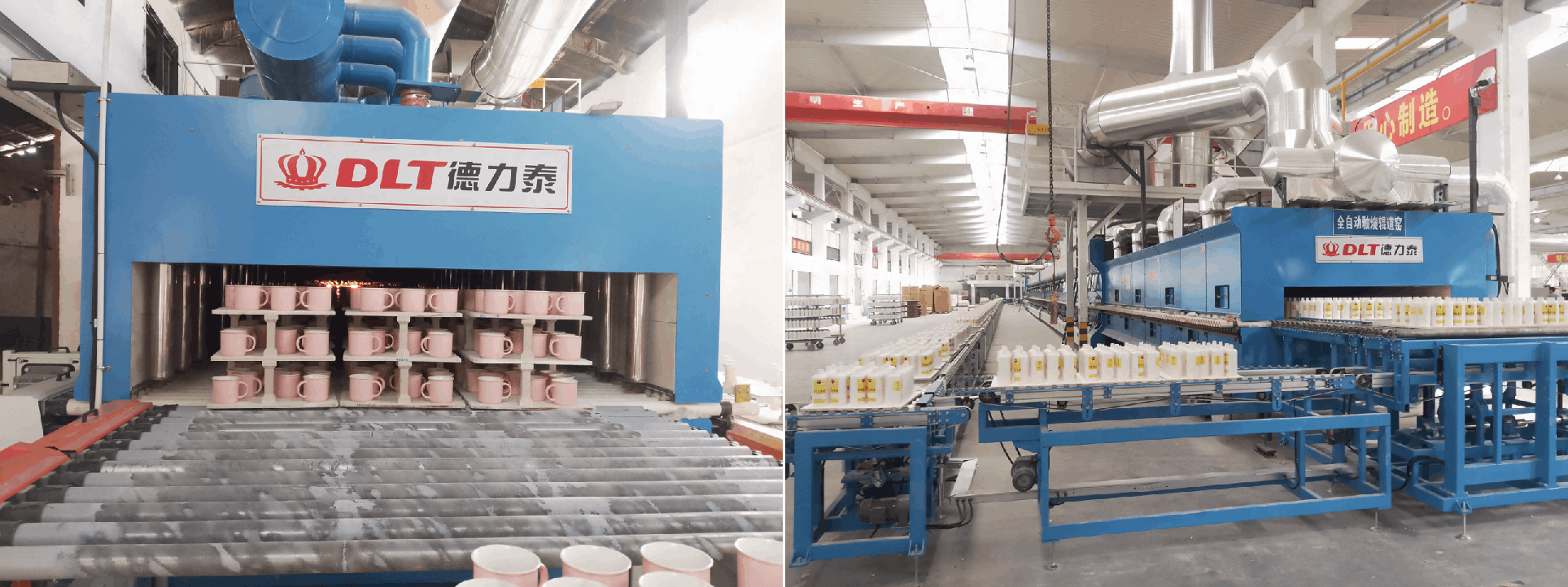

Tableware Production Firing Kilns

DLT offers a range of roller kilns and tunnel kilns that can be used for different processes such as biscuit firing, glost firing, decoration firing, and single firing, tailored to the different requirements of tableware products. These kilns are equipped with DLT's unique patented technologies including the DHR waste heat recovery system, KHI kiln comprehensive insulation system, PPC precise combustion control technology, OCE optimized combustion energy-saving system, DBS super energy-saving system, M-APP cloud control system, and MCG mobile messenger service. The firing kilns are designed with the concepts of wide body, small temperature difference, and high production capacity. They possess advantages such as high automation, low energy consumption, industrial aesthetics, and environmental friendliness.

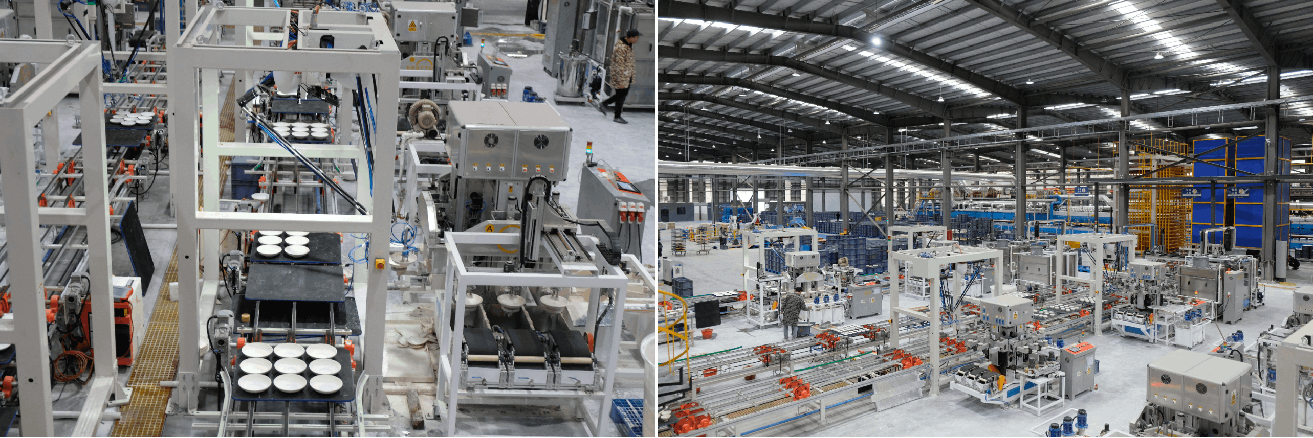

The industry's first CERAWORKS 4.0 high-end Intelligent EPC complete line for tableware production was put into operation in Jiangxi Jarwah in December 2022. This production line operates with full automation and intelligent control, ensuring high-quality operation. The complete-line digitized management mode increases labor efficiency by 50% and reduces personnel by 50% compared to traditional production models. The complete-line automatic conveying, glazing, and storage systems are pioneered in China.

Additionally, a customized tableware roller kiln for Liling Xiangqiang Ceramic has been specially designed, taking into account the kiln structure and configuration requirements for shaped products. Since its production, the kiln has operated stably, achieving excellent product quality. The new kiln has made breakthroughs in solving temperature differences and deformation issues, and reduced natural gas consumption by over 10% compared to peers, resulting in significant cost savings and value creation, earning consistent praise from customers. Recently, a complete line for tableware production was ignited and put into operation at Pecasa Company in India. This line adopts a full set of mature tableware process flows, starting from raw materials, forming, drying, biscuit firing, glazing, glost firing, decoration firing, inspection, packaging, and warehousing. It enhances the production capabilities and product quality for customers, resulting in significant benefits.

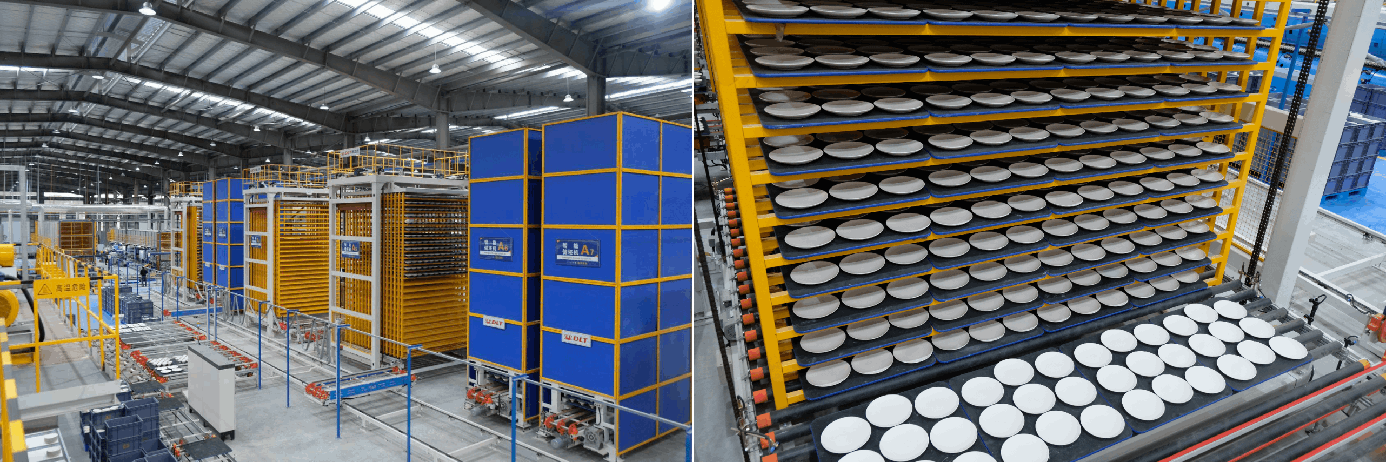

Intelligent Body Storage Machinery

DLT has developed intelligent storage body machinery based on the diverse categories and quantities prevalent in the tableware industry. This machinery enables automated three-dimensional storage blank with a height of up to 10 meters, effectively utilizing vertical space and enhancing the unit area productivity. Combined with surrounding automated conveyor lines and information software such as ERP, MES, SCDDA, WMS, PAC, and PLM, it enables categorized product storage and seamless integration with processes like shaping, drying, printing, and glazing. This integration helps establish a fully automated logistics and information system for the complete plant, creating a digital production system. This system achieves product personalization, manufacturing flexibility, design collaboration, supply agility, service proactivity, and intelligent decision-making, leading to a green and smart plant in the realm of intelligent manufacturing.

Vision System

To make machinery more agile and responsive during operation, DLT has innovatively applied vision systems to industry machinery. By utilizing image acquisition, image processing, and image recognition, the system achieves automation in detecting, identifying, and positioning tableware products. This is the first application of vision systems in automatic gripping and determination of tableware, in coordination with automatic glazing and printing. It enables unmanned operation, effectively improving production efficiency, reducing operational errors, and enhancing cost-effectiveness. This not only brings about innovative benefits for the enterprise but also elevates digital management for the enterprise to new heights.

DLT has always brought surprises through cutting-edge technology and practical actions in "smart manufacturing". By continuously innovating, the company has been at the forefront, leading the industry toward the development direction of green energy, automation, informatization, and intelligence. This has injected new vitality into the industry's future healthy development. Deepen your understanding of DLT's machinery and let's collaborate to explore new opportunities for development together.

(Huaying HUANG, HLT&DLT)

loading...

loading... 09 Oct 2023

09 Oct 2023