Recently, the signing ceremony for the complete production line project with a capacity of 150,000 pieces/day of roof tiles in Vietnam, was held grandly at the headquarters of the TAKAO Group! This endeavor marks the 8th comprehensive undertaking in collaboration with HLT&DLT Ceramics Machinery since 2017. As a significant strategic partner in the Vietnamese market, TAKAO's collaboration with HLT&DLT sets the industry standards in terms of both productivity and the refinement of craftsmanship, as well as energy consumption.

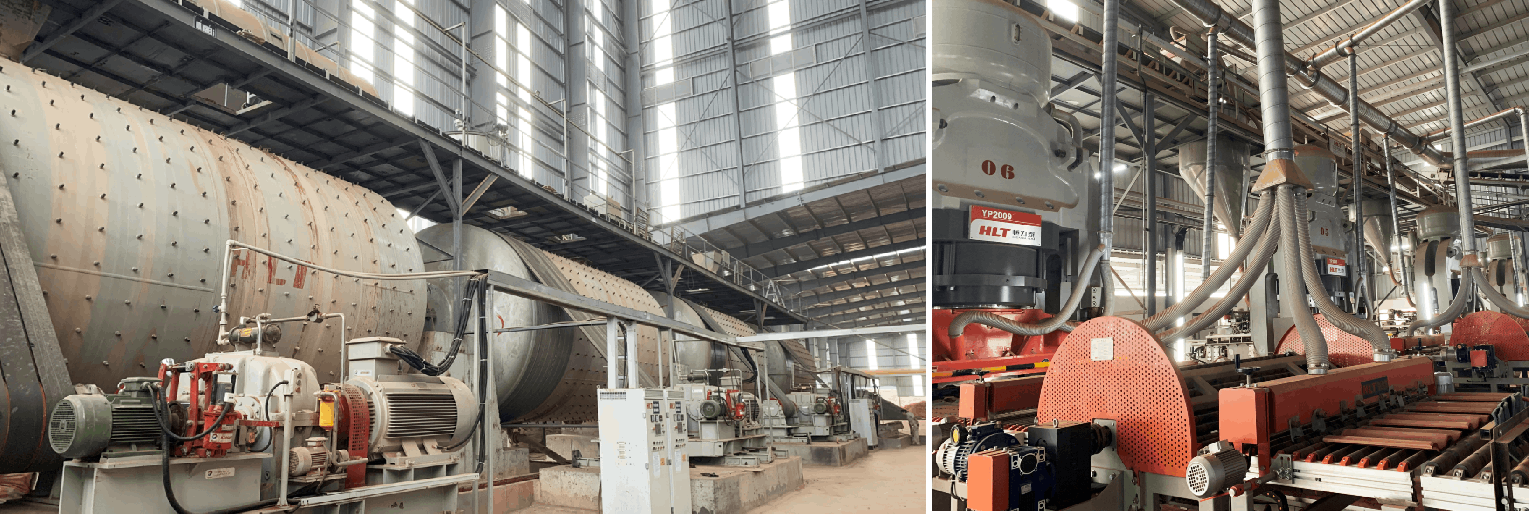

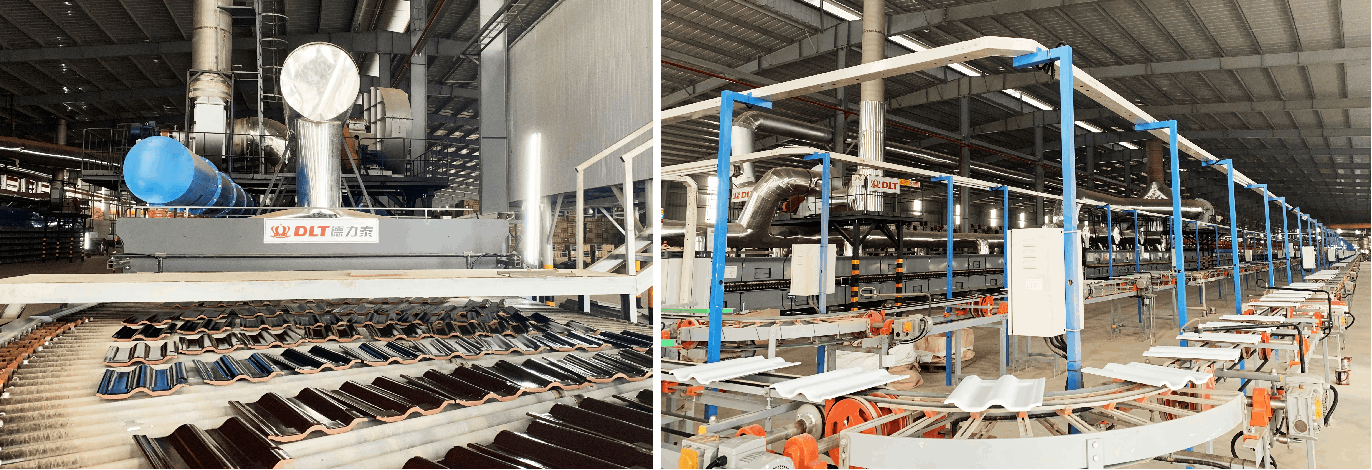

It is worth noting that among the 2 operational TAKAO plant areas, a total of 7 production lines have been commissioned (including 2 complete production lines of roof tiles, 1 complete production line of accessory tiles, 1 line for standard floor tiles, and 3 complete production lines for full polished glaze). These high-end automated complete-line machinery, including processes from pulverizing to forming and firing, have been exclusively introduced from HLT&DLT. According to customer feedback, since their commencement, these production lines have exhibited steadfast operational stability and have consistently delivered products of exceptional quality, consequently garnering TAKAO Group's resounding acclaim and commendation.

In order to pioneer the contemporary trend of affordable luxury in Vietnam, and to craft exquisite roof tiles of elevated aesthetics, TAKAO Group is resolute in its aspiration to both cater to market demands and ascend to a new echelon of heightened production capacity and exceptional quality. To achieve this ambition, the TAKAO Group once again demonstrates its firm commitment by embracing the introduction of HLT&DLT Ceramics Machinery's high-end automated "4.0 energy efficiency benchmark" complete-line machinery for roof tiles production – covering every stage from pulverizing to shaping and firing. Both parties engaged in sincere discussions and delved into details, particularly focusing on energy consumption, tile laying, temperature differentials, automation, and intelligence. Scientific processing and optimized design were carried out in these fields.

This project involves various components, including 4 sets of HLT Technology's 60T energy-saving intermittent ball mills, FaST series PST-12000 intelligent spray towers, and complete-line machinery for the glaze workshop. Additionally, there are 3 units of HLT Industry's YP3009T automatic hydraulic presses, DLT Technology's Industry "4.0 energy efficiency benchmark" roof tiles firing kiln (W3100/L268.8M), EM series five-layer recirculating dryers (W3200/L64.4M), pre-kiln drying and glazing lines, and other complete sets of auxiliary machinery. The primary production specifications are for high-end roof tiles measuring 325*425mm, with a designed daily output of 150,000 pieces.

It is understood that this production line is equipped with advanced technology, meticulously designed, and incorporates several patented innovations from HLT&DLT. As currently the most representative roof tile production in Vietnam, it showcases the highest capacity and exemplifies intelligent automation. Upon commencement of operations, it will display three prominent advantages: low energy consumption, high output, and exceptional efficiency, thereby enabling TAKAO Group to continuously surpass and enhance its production capacity and value, further solidifying its brand status.

Over the years, TAKAO Group's choice of HLT&DLT Ceramics Machinery is not only a testament to trust but also a recognition of HLT&DLT's commitment to pioneering low energy consumption and setting quality benchmarks in the industry. This choice reflects a profound sense of corporate social responsibility and dedication. In its endeavor to construct a digitalized and intelligent production system, drive industry transformation and promote high-quality development, HLT&DLT Ceramics Machinery is backed by robust technical prowess, a distinctive approach, a pragmatic service orientation and a strong brand reputation, playing a pivotal role in the ascent of the Vietnamese building ceramic industry. Looking ahead, there is anticipation for HLT&DLT and TAKAO to co-create more splendid achievements, contribute to society, and establish industry benchmarks.

The signing ceremony received exceptional attention from TAKAO Group, with the presence of Chairman Trần Ngọc Hưng, Vice Chairman Tạ Hùng Sinh, Chief Financial Officer Phạm Thị Quỳnh Hoa, as well as Lingxiang YUAN, General Manager of HLT&DLT Ceramics Machinery's Vietnam Sales District and Sales District Engineer Wenjing XIE. Additionally, Yuanyou ZHENG, Deputy General Manager of HLT Technology, gracing the event. Together, they collectively attended the signing ceremony, which culminated in the successful contract signing between the two parties. Chairman Trần Ngọc Hưng represented TAKAO Group, while Lingxiang YUAN, General Manager of HLT&DLT Ceramics Machinery's Vietnam Sales District, represented HLT&DLT.

loading...

loading... 16 Aug 2023

16 Aug 2023